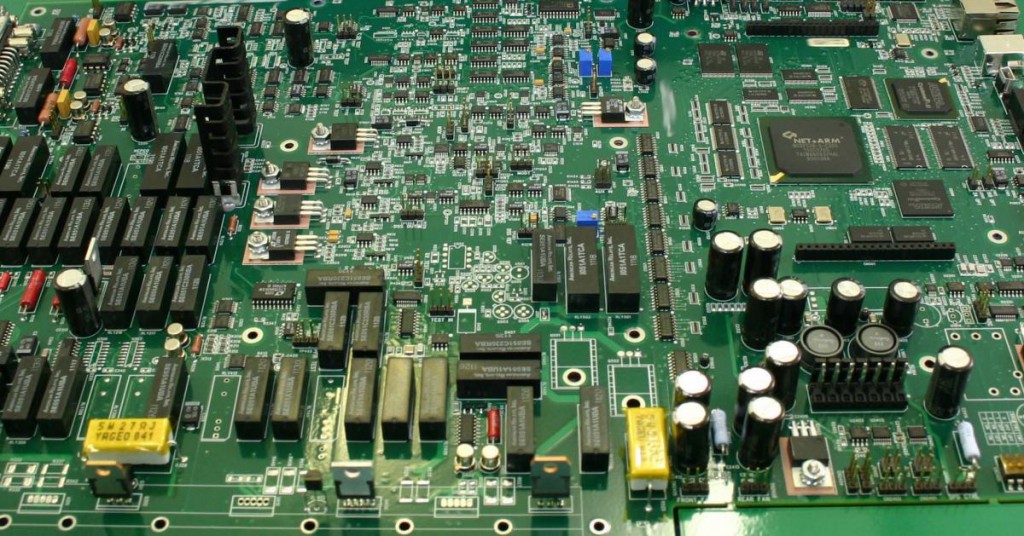

A new high-density direct connection for printed circuit boards has been placed on the market by Phoenix Contact. Dubbed the SDDC 1.5 connection system it offers four to thirty-two conductors using “SKEDD” plug-ins. Using the SDDC 1.5 eliminates the need for a header and soldering during the manufacturing process, saving money. Using a push-in spring connection allows wires to be terminated to the connector. It has also been designed with solid, stranded wires that include a ferrule which can be pushed into the terminal block while the spring clamp stays closed. Removing the wires is simple by pressing the orange spring lever with a regular screwdriver. It has a range of 3.5-mm centerline and works with 24 to 16 AWG wires, can handle currents up to 8 A at 300 V UL, and provides the push-in spring connection. Its double row design is the latest in SKEDD Technology that uses a gas-tight connection.

The SDDC 1.5 connection system’s contact zone consists of two flexible parts that allow contacts to be easily adjusted with the use of plated through-holes on the printed circuit board. The good news for manufacturer’s is that the design is so easy, it will not add to the cost of manufacturing, in fact, it can save on the production costs. When inserted there is enough force that will create a gas-tight connection, requiring nothing special for the PCB. The connection stability of the board is achieved by locking pins that expand with the push of the orange locking tabs. It can potentially be used in building automation, HVAC systems, elevators and escalators, and white goods.

Also Read: VIEW ON PCB DESIGN AND IMPLEMENTATION TODAY AND IN THE FUTURE

Features include;

- Allows you to save time during wire termination with its push-in connection

- There is no need for a plug and header combination with its direct plug-in onto the PCB

- Cost effective, only one component is necessary

- Free positioning

- Secure locking

- Up to 25 mating and unmating cycles, for easy replacement

- Intuitive use through color coded actuation lever

- Quick and convenient testing using integrated test option

The SDDC 1.5 connection system is the newest high-density direct connection for printed circuit boards, that reduces manufacturing costs while allowing free positioning on the printed circuit board. This is good news for the early adopters of this connection system, the implementation process does not require additional parts, the opposite is true, it only requires one component, does not require soldering and can be manufactured without using any tools. Adding the integrated test option is simply another reason for considering the use of this connection system when necessary.

Also Read: WHY IT IS NECESSARY TO CONTROL HUMIDITY IN PCB ASSEMBLIES

There is no doubt that the printed circuit board is the most important aspect of any technological project. Meeting the industries demand for smaller, more effective, devices will continue to be a part of the PCB manufacturer’s responsibility. The SDDC 1.5 connection system is an example of the latest in technological advances that we continue benefit from. We look forward to the next advancement in PCB manufacturing!

References