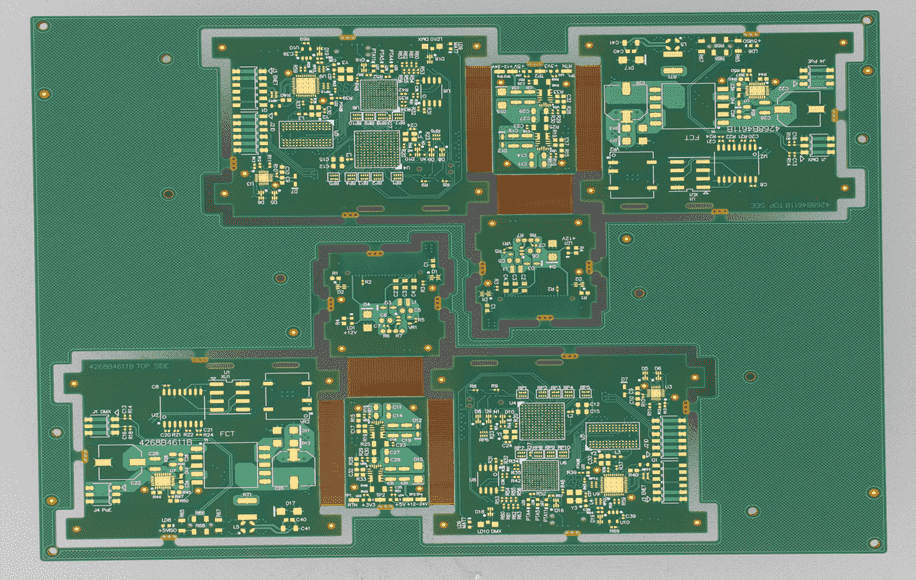

Rush PCB is a renowned manufacturer of all types of PCBs. We are well-known in the electronic industry as multilayer PCB manufacturers. We make rigid, rigid-flex, and flex multilayered PCBs, as well as HDI multilayered boards.

Introduction to Multilayer PCBs

The electronic industry uses several types of PCBs with many layers. These include:

- Single-Layer PCBs

- Double-Layer PCBs

- Multi-Layer PCBs

Single-Layer PCBs: For simple circuits, it is usually enough to use a single-sided PCB. Whether the circuit uses through-hole components or SMD, the single-sided board typically has copper traces only on one layer—for through-hole components, the bottom layer has the copper traces, while for SMDs, the upper layer has the traces.

Double-Layer PCBs: With the increase in circuit complexity, a single layer is not enough and designers need copper traces on both, top and bottom layers of the board. This is the double-layer PCB, and it may have vias connecting the top and bottom traces as necessary. Designers use both through-hole and SMD components for double-sided boards.

Multi-Layer PCBs: When circuit complexity increases further, designers need more layers to interconnect the components placed on the top layers. These are multilayer boards, and may have 1-40 layers or more. Various types of vias connect the different layers, including through-hole vias, buried vias, and blind vias. Using multiple layers helps to bring down to the size of the PCB to a manageable level.

Get free quote on your multi-layer Board.

Advantages of Multi-Layer PCBs

As a multi-layer PCB manufacturer, Rush PCB makes high quality PCBs for our customers. The advantage of using a multi-layer board is the designer can use multiple layers for all the traces they require to connect their components on the board. This helps to realize a complicated circuit for a small product such as a mobile phone or a pocket recorder.

A multilayer PCB also increases the flexibility of a designer to better control single-ended and differential impedance, including improving the signal integrity for high frequencies.

Most manufacturers of electronic products use multilayer PCBs as they offer high design flexibility, stability, and reliable device performance. Multilayer PCBs allow them to use large-scale integrated circuits, and they can have products with high precision, high density, and high levels of digitization.

Give us a call and start the process of converting your design to reality.

Structure of Multilayer PCBs

As a multi-layer PCB manufacturer, Rush PCB starts with the core, usually an FR4 material that gives the board its rigidity. Both sides of the core have a copper clad affixed to the core with epoxy resin. We build up each layer with a prepreg to act as an insulation and a dielectric along with a copper clad to build the stackup. We adjust the thickness of the prepreg and the copper clad in each layer to reach the final board thickness.

The copper clad in each layers undergo photo-imaging, etching, and drilling before we add it to the stackup. The drilling is necessary for making the vias.

The top and bottom layer of the board undergoes solder resist printing, surface finish, and legend printing, before the board moves to assembly.

For more information on Rush PCB multi-layer boards, please call us today or visit our contact us page.