Introduction to High Frequency PCBs

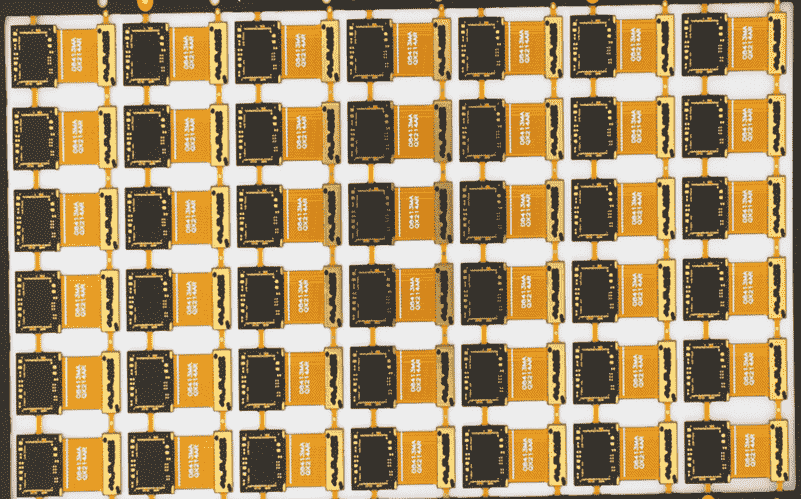

As a high frequency PCB manufacturer, Rush PCB makes both rigid and flexible types of boards. Our high frequency PCBs offer faster signal flow for frequencies up to 100 GHz. Although numerous materials are available for high frequency operation, Rush PCB uses materials for HF PCBs that exhibit a few common features like low dielectric constant or Dk, low dissipation factor or Df, and low coefficient of thermal expansion or CTE. We use the materials for high frequency PCBs also for our boards using HDI technology. Industries using our high frequency PCBs include RF microwave, telecommunications, high speed communications, and more.

For a free quote on your RF PCB design, visit our contact us page

Materials for High Frequency PCBs

We use special materials for achieving the high frequency operations of our HF PCBs. Depending on the range of signal speeds of the application, we use a variety of substrate materials that are the best suited.

From cost considerations, FR4 is the least expensive, while Teflon is the most expensive material for fabricating high frequency PCBs. However, high frequency performance of FR4 is rather limited and there is a significant drop as the signal speed crosses 1.6 GHz.

Several new types of substrates are now available, and they exhibit excellent performance at high frequencies. These new materials are suitable for flex circuits also, and along with Teflon, have very low values for Dk, Df, water absorption, and they can survive the toughest environments.

For frequencies above 10 GHz, we typically use these newer generation materials as substrates for our HF PCBs. Along with Teflon, these new materials are the most suitable for both rigid and flex type of high frequency PCBs.

At Rush PCB, we use materials from many suppliers for fabricating our HF PCBs. Our suppliers include Panasonic, DuPont, Taconic, Isola, and Rogers. These manufacturers make these materials specifically for low loss, and low Dk.

Call us today, or visit our contact us page for converting your RF design to reality.

Rush PCB Capabilities for High Frequency PCBs

- Trace width – 2 mil

- Spacing air gap – 3 mil

- IPC class – 2/3

- Net List test – Flying Probe

- Testing & Inspection – AOI, TDR, Differential Impedance

- Routing & Drilling – Scoring/routing, countersink/counter bore, laser routing, blind/buried vias, micro vias, stacked vias

- Lamination – 1-40 layers, Sequential lamination, Vacuum lamination

- Plating – Non-conductive/conductive via fill, Castellation, Plated radii, Plated edges, Plated milled cutouts, Soft bonding gold, hard gold body, immersion gold, ENTEK (OSP), Immersion silver, HAL (standard/Lead-free)

- Materials – Rigid, Rigid-Flex, Flex, Kapton, high-speed and RF materials, mixed materials

Circuit Materials and High Frequency Losses of PCBs

Rush PCB is an expert in the design and fabrication of high frequency PCBs and we have considerable experience in this field. We use the most optimum materials for fabricating the board suitable for the range of frequencies for the application. At the same time, we also make sure the material we are using has the lowest Dk and Df. This ensures that the loss due to the material at high frequencies is the least.

Industries We Serve

Several industries use our high frequency PCBs. These include:

- Wireless communications

- Wearable Electronics

- Web Enterprises

- Unmanned Vehicles

- Test & Measuring Instruments

- Semiconductors

- Opto Electronics

- Military Equipment

- Medical Instruments

- Industrial Controls

- Consumer Electronics

- Automotive Industry

- Aerospace Industry

For more information on High Frequency PCBs, contact us or call us +1 408-496-6013.