Various industries are now using LEDs or Light Emitting Diodes for lighting purposes. These solid-state lighting devices convert electricity into light whencurrent passes through the semiconductor junctions of the LEDs. Compared to traditional light bulbs, LEDs are far more efficient, as they can convert more than 80% of the input energy to light. They are also longer lasting than most other types of light bulbs. Their environmental friendliness and small size add to their advantage.

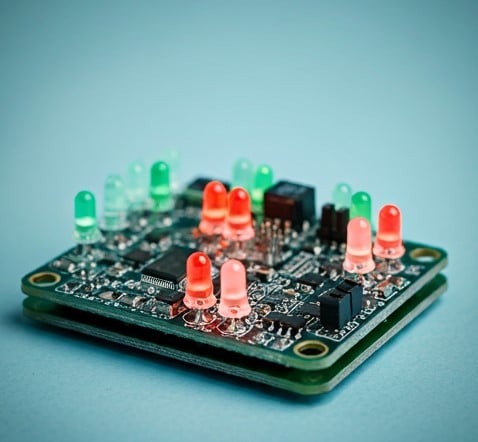

At Rush PCB Inc., we offer LED PCBs or printed circuit boards that we design expressly for mounting LEDs. Our LED PCBs are thin boards that provide physical support for the LEDs, and further help by transferring heat away from the LED bulbs. Our boards enhance the performance of the LEDs mounted on them and prevent damage to them.

Our LED PCBs, also known as MCPCBs or Metal Core PCBs, have brought great progress to the LED industry. They have been instrumental in increasing the lifespan of the LEDs while enhancing their performance significantly.

Why LED PCBs?

Although LEDs are highly efficient in converting electricity to light, they generate some heat when operating at high power. Unless this heat is removed quickly, it may cause thermal runaway, thereby destroying the LED. The metal core in the LED PCB helps to distribute the heat very quickly.

LED applications in industries prefer to use metal core LED PCBs as the metal core has a higher ability to dissipate the heat from the LEDs, keeping them operating within their specified temperature range. We typically use Aluminum as the metal core for LED PCBs.

Metal in LED PCBs

We make metal-core PCBs using copper, aluminum, or stainless steel. This is because the higher thermal conductivity of these metals helps in removing heat faster. While copper offers the highest thermal conductivity, it is also more expensive. Users, therefore, prefer aluminum instead, as it offers a good compromise between performance and cost.

Aluminum also offers higher versatility. We use different types of aluminum for various purposes, thereby providing specialized LED PCBs. All these aluminum types are highly effective and they offer good results:

▪ Flexible Aluminum

We use flexible aluminum as it offers great insulation and flexibility. A combination of ceramic fillers and Polyimide resins provide the insulation. The combination allows us to offer high thermal conductivity along with good flexibility.

▪ Hybrid Aluminum

Merging aluminum with a non-thermal material like FR4 offers high thermal conductivity along with high rigidity.

▪ Multi-Layer Aluminum

We use multi-layer aluminum for highly complex PCBs, as it is an excellent choice for high thermal conductivity, outstanding insulation, and good mechanical strength. These PCBs typically have more than two layers made of thermally conductive adhesives.

Aluminum LED PCB Construction

These are the most popular types of LED PCBs. The substrate sits on an aluminum alloy base, mostly made from an alloy of aluminum, magnesium, and silicon. We alter the properties of the materials to meet individual application needs. Typically, these PCBs consist of several layers:

▪ Base Layer

The base layer is the aluminum alloy sheet, on which the rest of the PCB rests. Being highly heat-conducting, it distributes the heat and disperses it.

▪ Thermal Insulation

This layer is made of a ceramic polymer, protecting the board from thermal and mechanical damage. As the circuit operates, this layer absorbs heat from the LED and transfers it to the base or aluminum layer.

▪ Circuit Layer

This layer has the copper circuit laid out according to the circuit design of the LED PCB.

Advantages of Aluminum for LED PCBs

Using Aluminum for LED PCBs offers many benefits like:

Lower Costs

As aluminum is abundantly available around the world and is relatively easy to

mine and refine, it is less expensive compared to other types of metals. We

use aluminum for PCBs as it is a cheaper alternative compared to other

methods of transferring heat, such as using heat sinks. Using aluminum

reduces the overall cost of producing our customers’ boards.

Enhanced Environmental Performance

As aluminum is non-toxic and can be recycled, it offers an enhanced

environmental performance—it shrinks the carbon footprint of producing the

PCB. Aluminum is also easier and safer to dispose of at the end of the LED PCB’s life.

Improved Durability

A backing of aluminum makes the fiberglass or ceramic PCB more durable and

more resistant to damage during manufacturing, assembly, and use. The

aluminum backing improves the LED PCB’s durability, allowing them to be used in harsher environments.

Reduced Weight

As aluminum is lighter than other alternatives like copper and stainless steel, it is easier and cheaper to handle and ship aluminum LED boards. The

combination of lightweight, higher reliability, and robustness makes aluminum LED boards ideal for use in vehicles and aerospace.

Types of LED PCBs

We use SMD or surface mount device LEDs or COB or chip-on-board LEDs on

most of our LED PCBs. We mount SMD LEDs on the surface of the board along with other SMD components. For COB LEDs, we arrange the dies or ICs in a circle or a regular polygon and directly bond them to the PCB, sealing them together with glue. Then we use either flip-chip or wire bonding to bond the COB LEDs to the PCB.

LED PCB Assembly Process

Assembling an LED PCB involves mounting all the necessary electronic

components including the LEDs on the PCB.

SMD LEDs

For SMD-type LEDs, we mount them along with other SMT components on the board. For this, we follow the regular process:

- Silkscreen printing the solder paste on the PCB

- Solder paste inspection

- Component placement on the PCB

- Reflow soldering to bond the components onto the PCB

- Automated optical inspection

COB LEDs

For COB-type LEDs, we directly bond them to the PCB without surface mount

or reflow soldering. For bonding, we use one of two processes:

Wire Bonding

We use gold wires to connect the chips to the positive and negative electrode

pads.

Flip-Chip

Flip-chip COB LEDs typically have solder balls at their bottoms. After placing

them on the PCB, we use force and high temperature to allow the solder balls

to melt, thereby bonding the chip to the PCB. We then use an encapsulation

glue to seal the COB LEDs to the PCB.

Through-Hole LEDs

Through-hole assembly requires passing component leads through holes in the

PCBs and soldering the leads onto copper pads. Although providing stronger

and more durable connections, this method is no longer as popular as using

SMD LEDs.

Why Rush PCB Inc. for LED PCB Assembly?

If you want to take full advantage of all the benefits that LED PCBs have to

offer, come to Rush PCB Inc., as we have decades of experience in fabricating

and assembling LED PCBs. Lights from LEDs are rather temperature-sensitive

and require complex circuit designs to compensate. We offer the necessary

expertise and world-class equipment for fabricating and assembling LED PCBs. We have been working with LED lighting since the early days of the

technology, and we have the necessary knowledge and skills to help you with

your LED project.