Hdi Capability

Template: desktop two

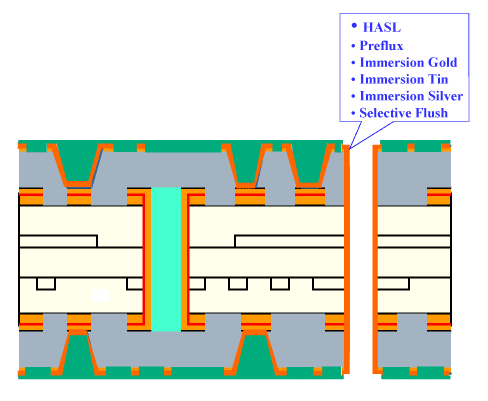

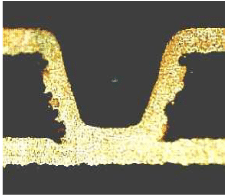

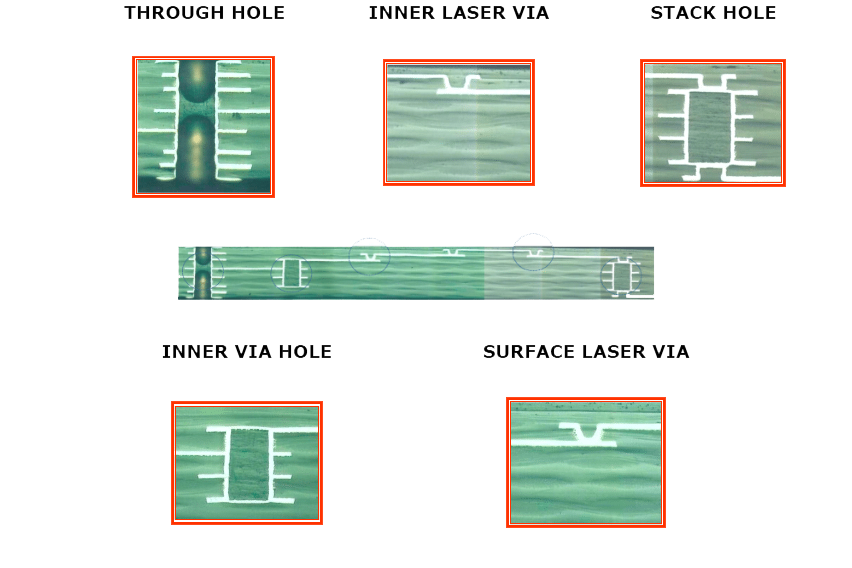

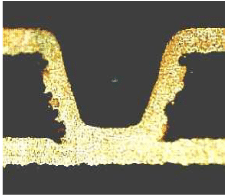

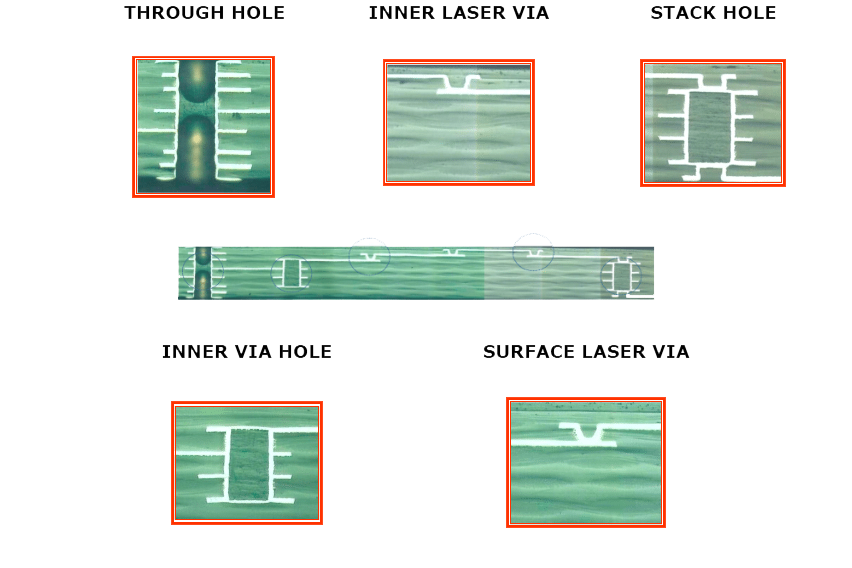

HDI Technology in Hole

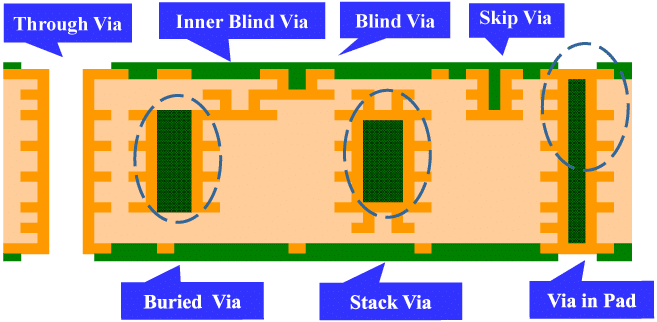

High Density Interconnection

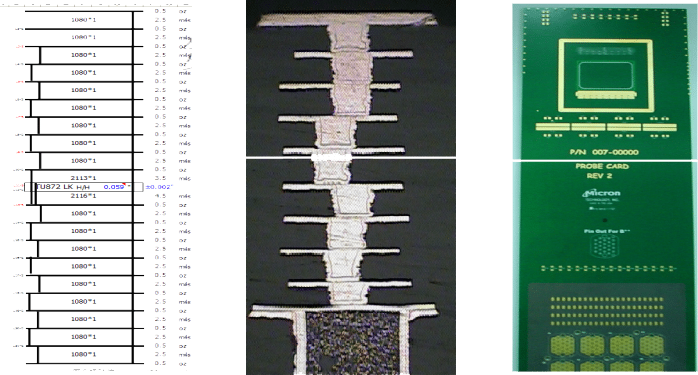

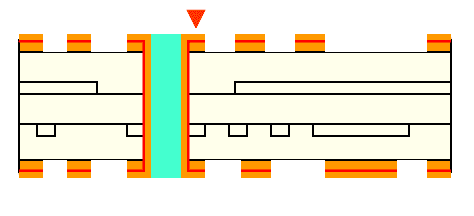

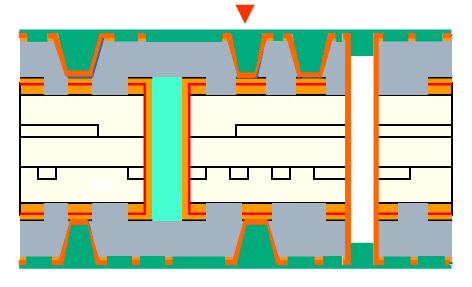

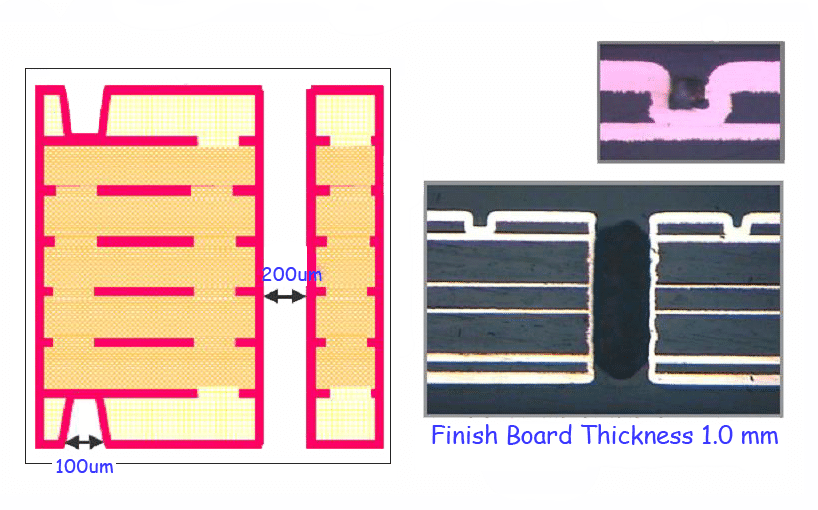

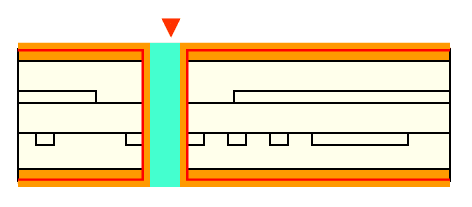

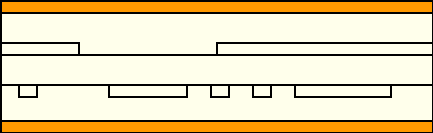

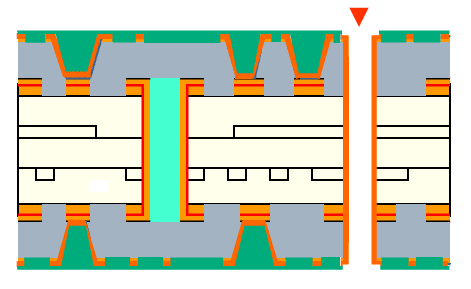

Blind & Burried 9+2+9 Laser Drill

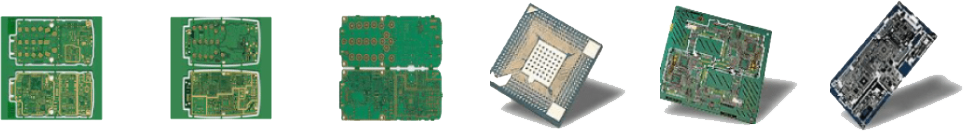

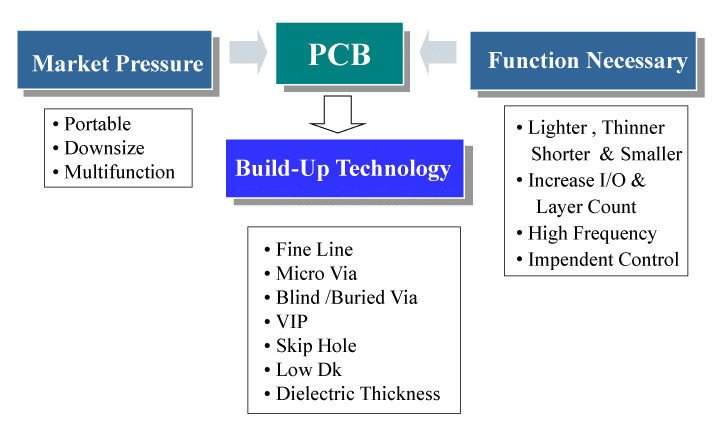

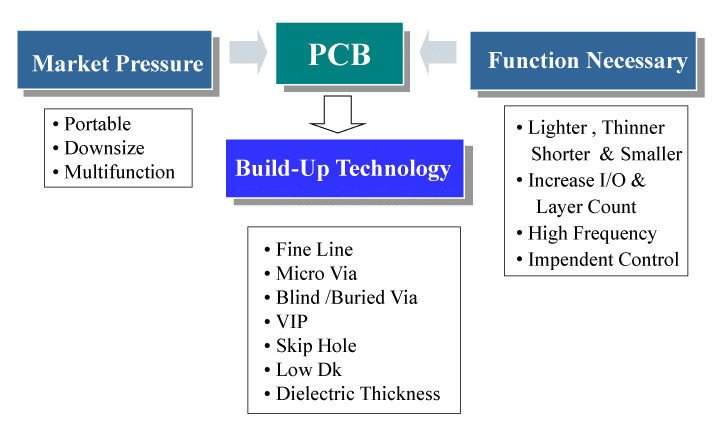

Market Trend vs. Technology Solution

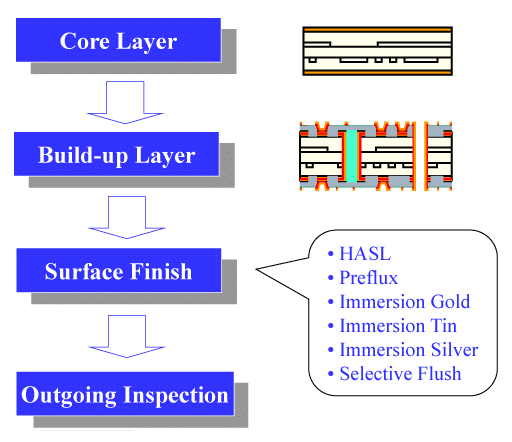

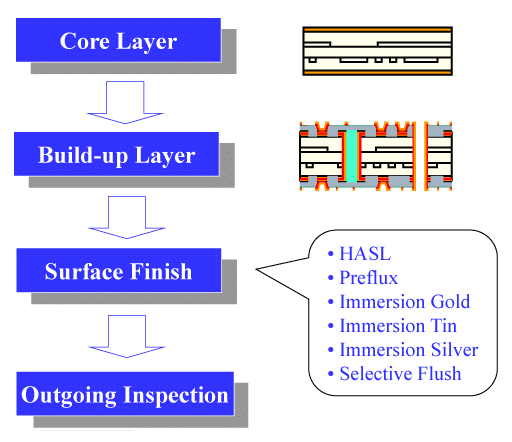

HDI Process Flow

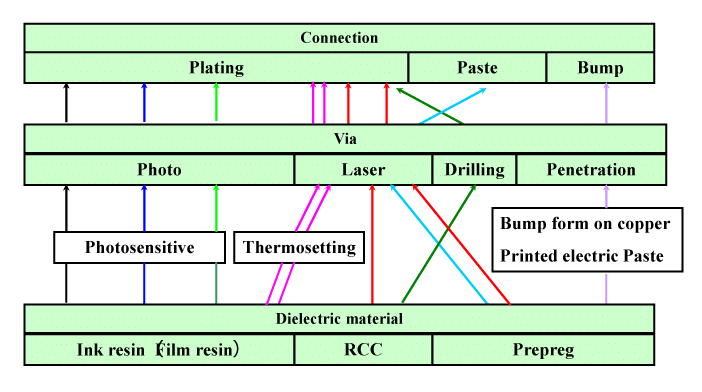

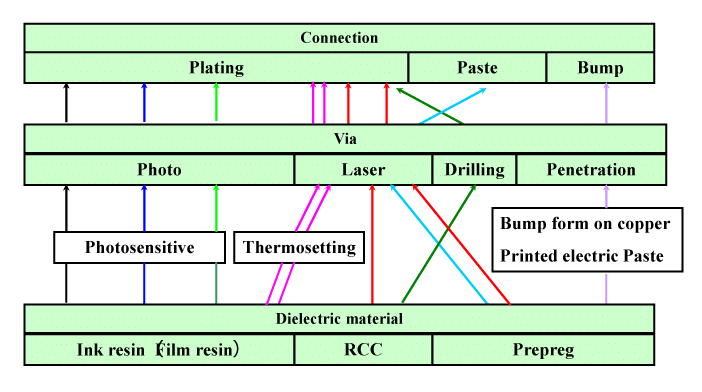

Main Process of Build – up Layer

Construction Materials

Material Type

- FR 4 Tetra Function ( Tg. 130 – 140 ℃ )

- FR 4 High Tg ( Tg. 160 – 180 ℃ )

- RCC ( Tg. 150 ℃ & Tg. 185 ℃ )

- Ink ( VIL )

Comparison of Material

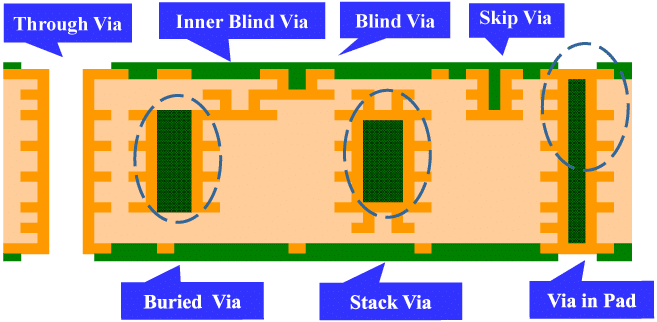

Comparison of Via Technologies

Comparison of Blind Via

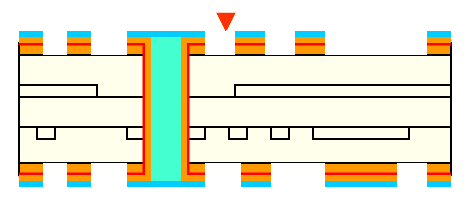

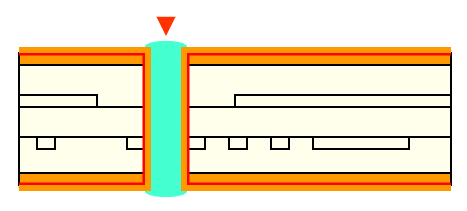

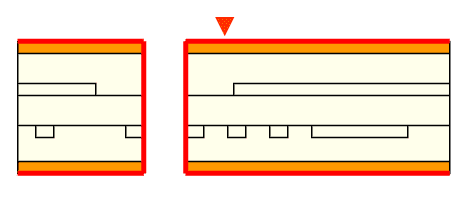

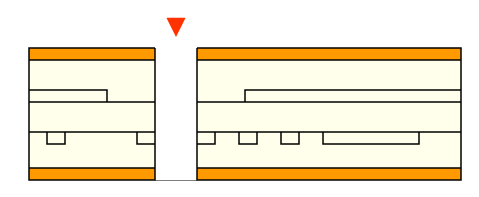

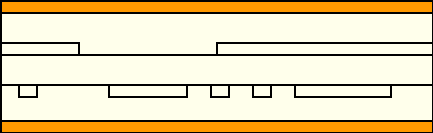

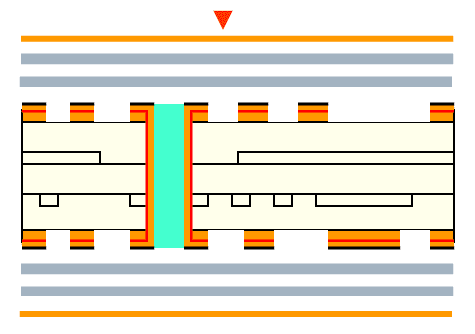

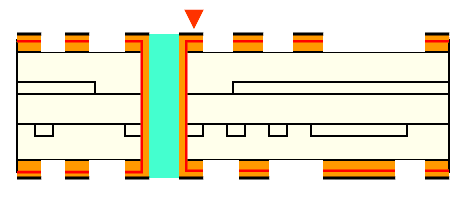

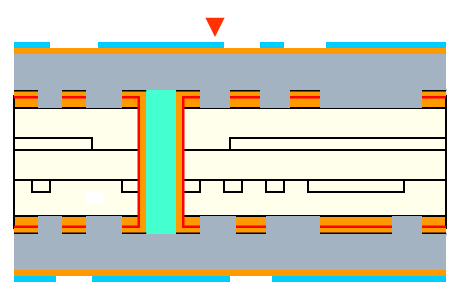

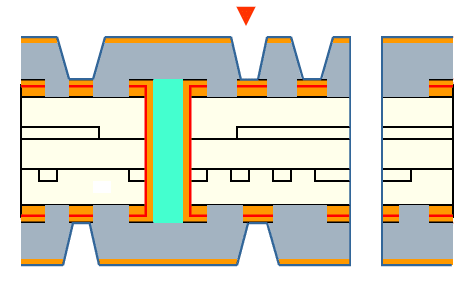

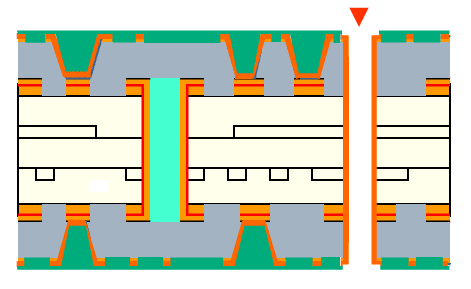

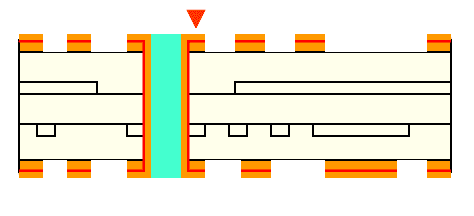

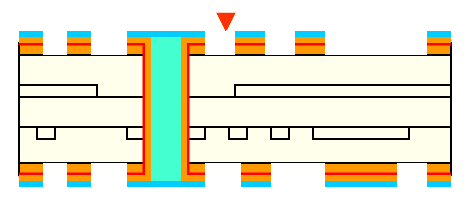

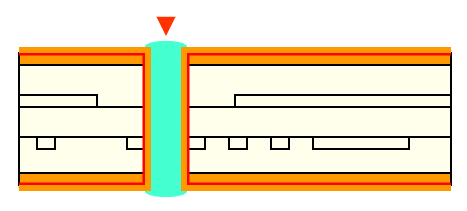

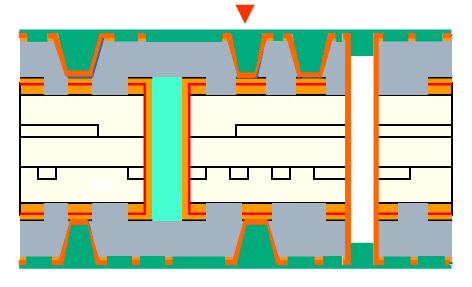

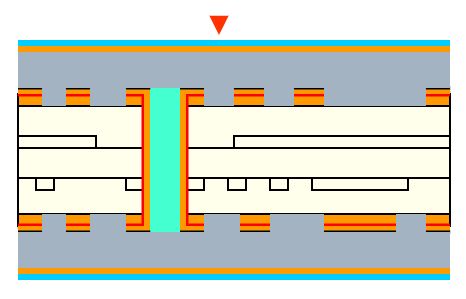

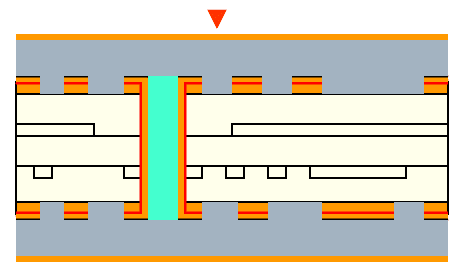

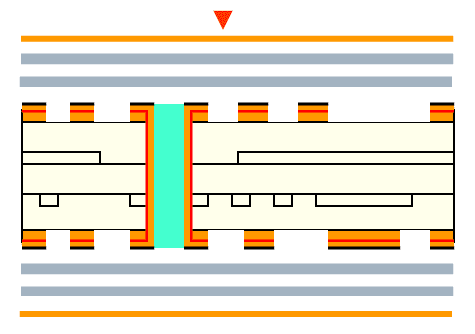

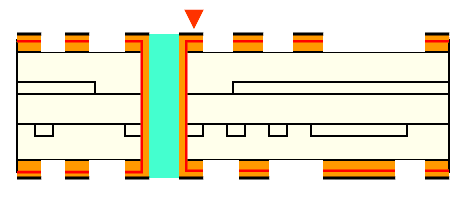

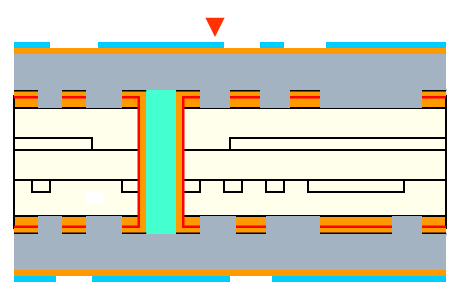

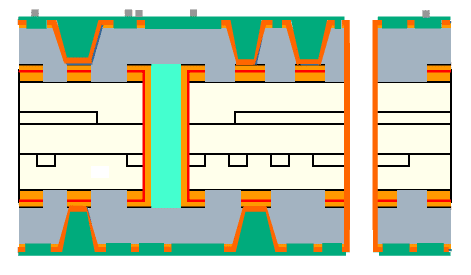

Build-up for 2 + N + 2

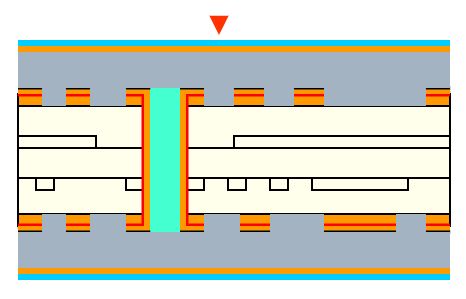

1+6+1 without buried, extend to 1+N+1

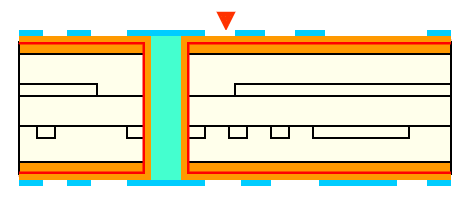

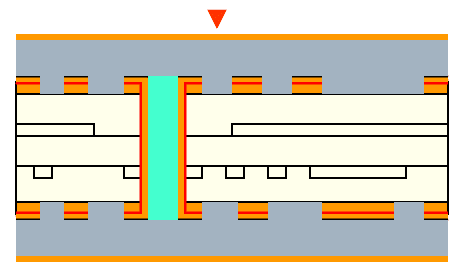

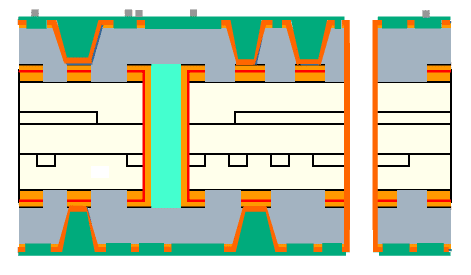

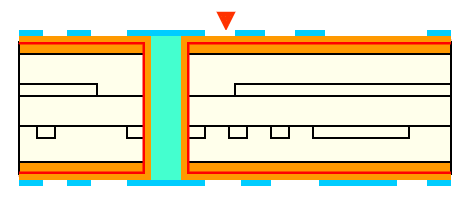

1+4+4+1 with buried via, extend to 1+N+N+1

Black Oxide Treatment

D.F. Exposure / Developing

Dry Film Lamination

I.V.H.Grinding ( for thickness >= 60 mil )

Inner Via Hole Plugging ( for thickness >= 60 mil )

Electroless Copper Plating

I.V.H.(Inner Via Hole) Drilling

I.V.H.(Inner Via Hole) Drilling

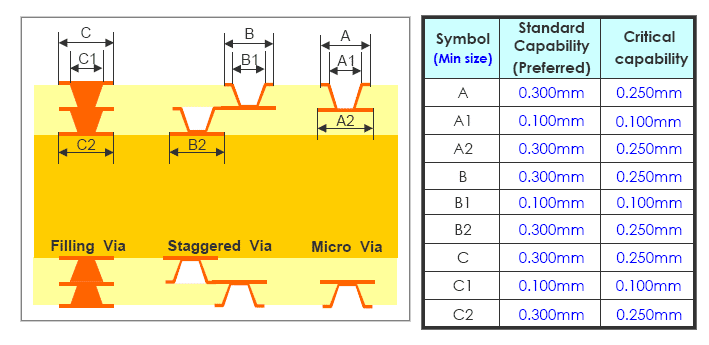

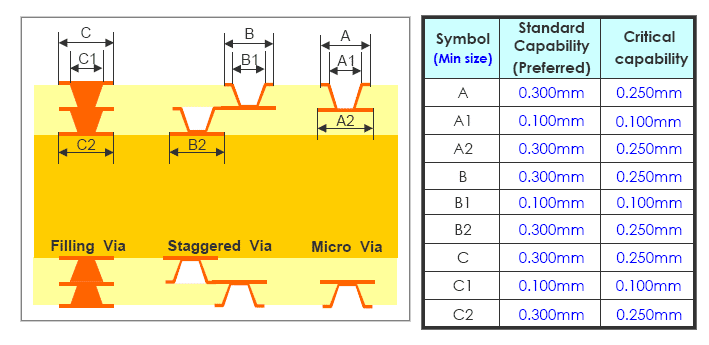

Blind via Capability

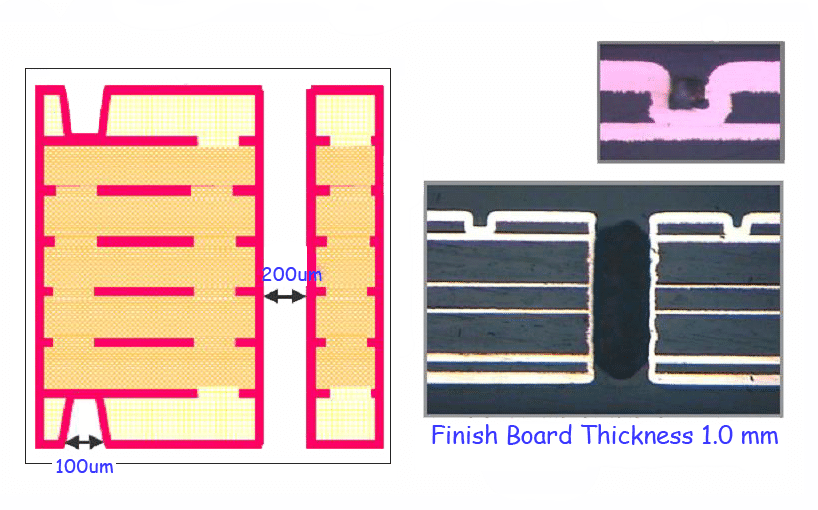

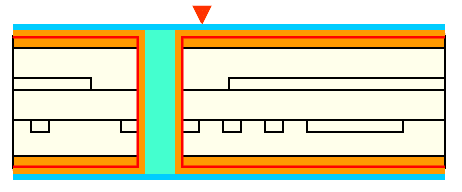

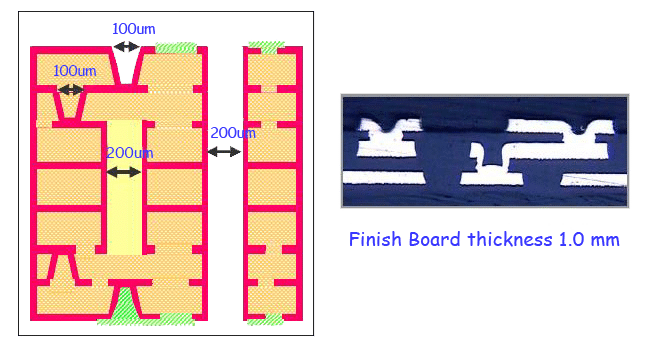

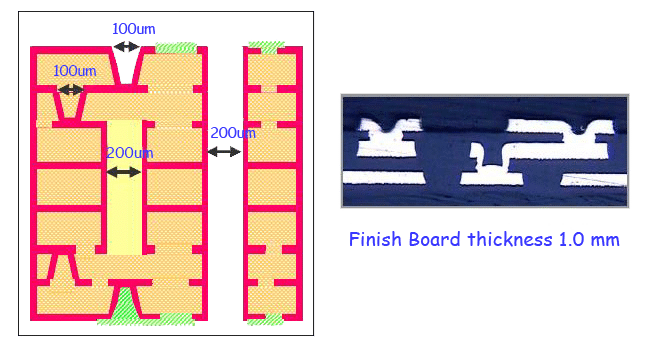

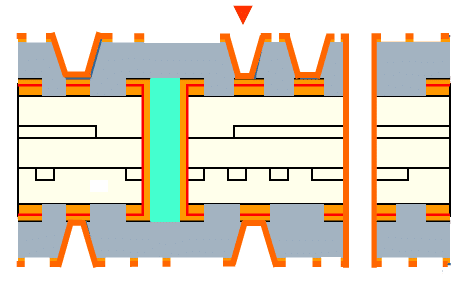

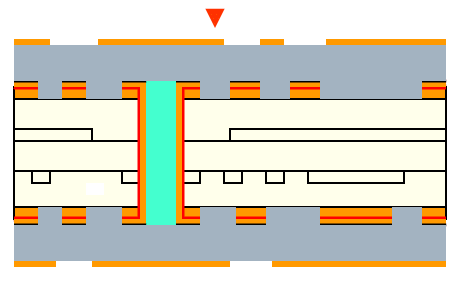

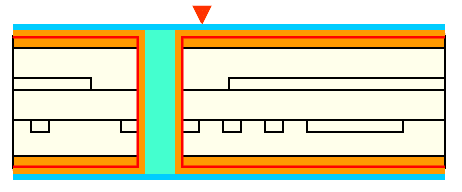

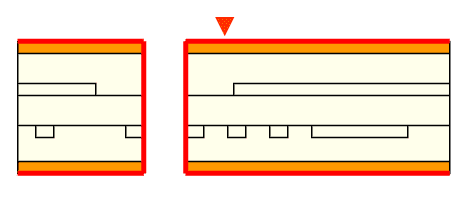

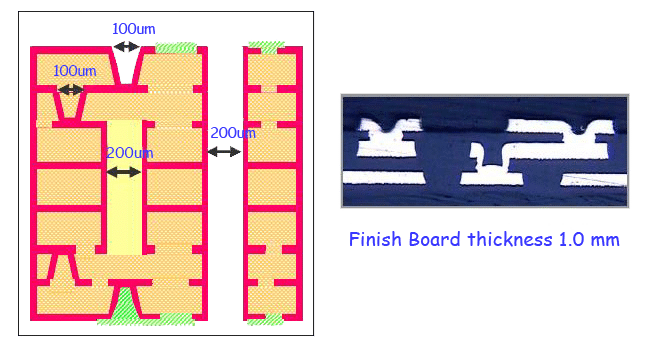

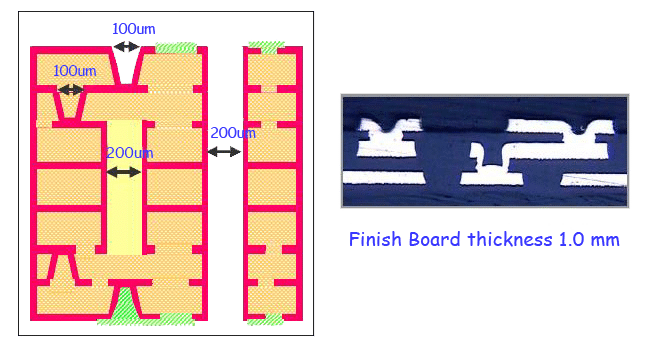

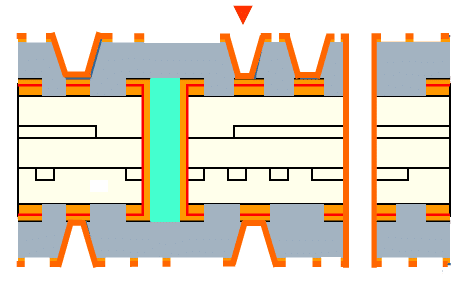

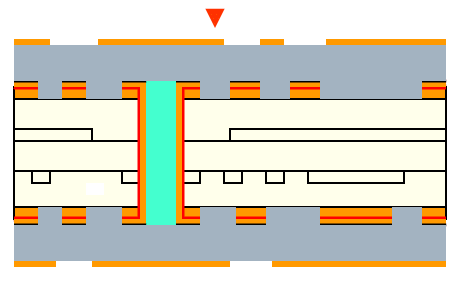

2+4+2 Staggered via, extend to 2+N+2

2+4+2 Staggered via, extend to 2+N+2

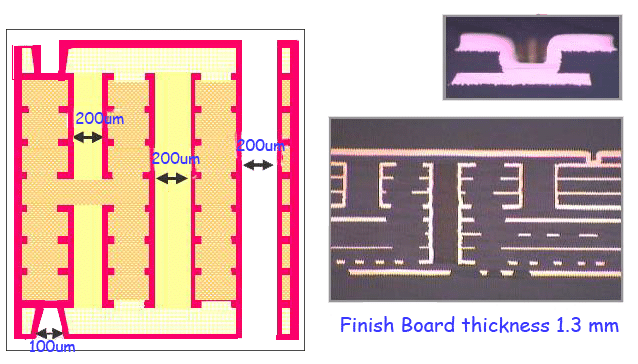

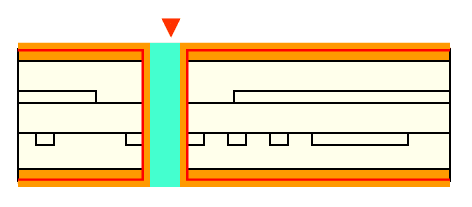

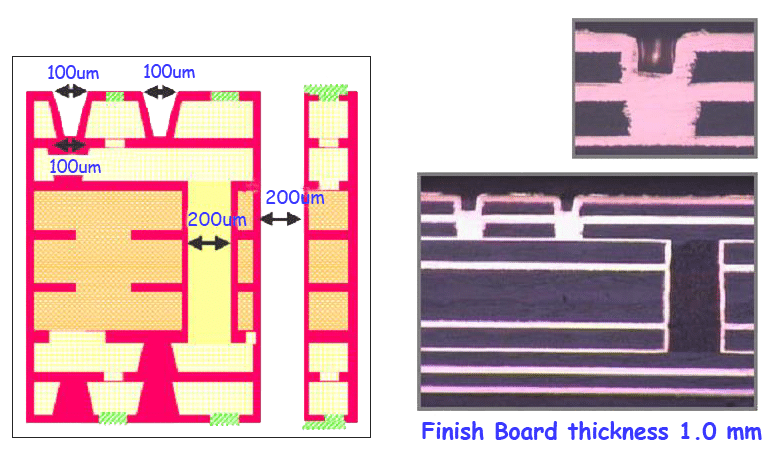

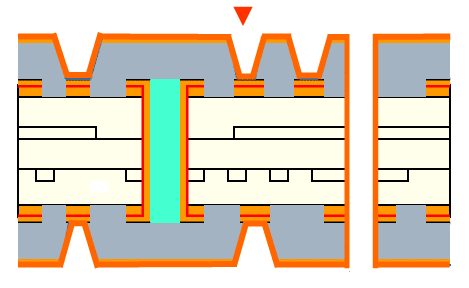

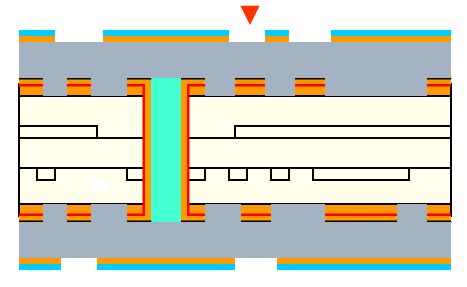

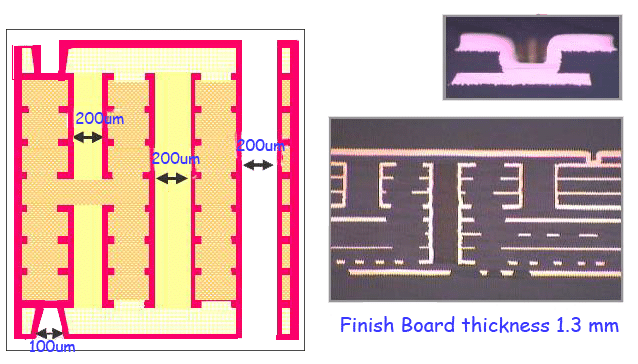

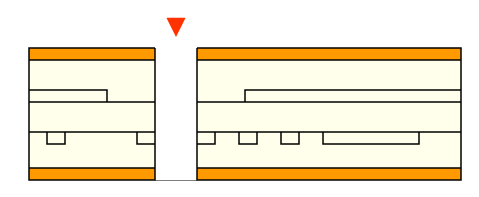

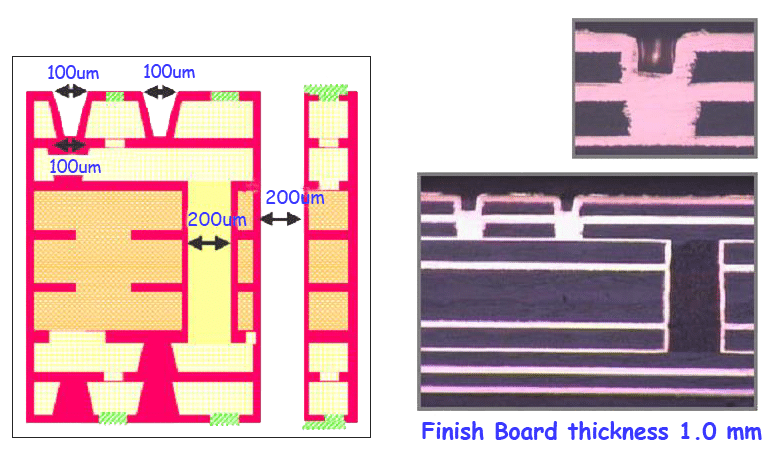

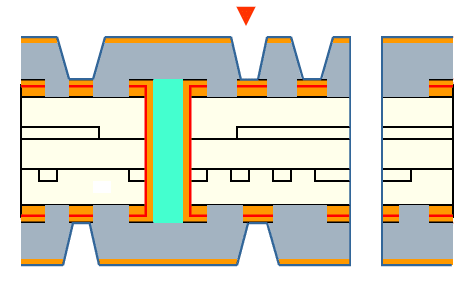

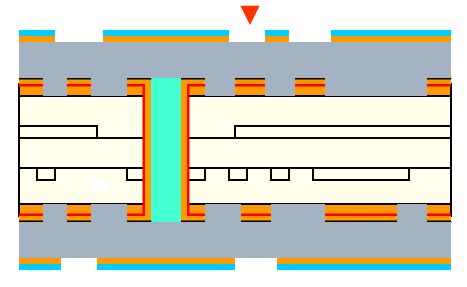

2+4+2 laser via on laser via

Solder Mask Printing

Dry Film Lamination

Lamination

Prepreg Layup

Black Oxide Treatment

D.F. Exposure / Developing

D.F. Exposure / Developing

Electro Plating

Desmear / Electroless Copper Plating

D.F. Strip

Etching

S/M Exposure / Developing

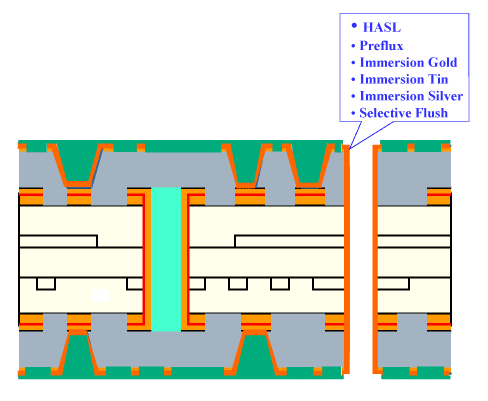

Surface Finish