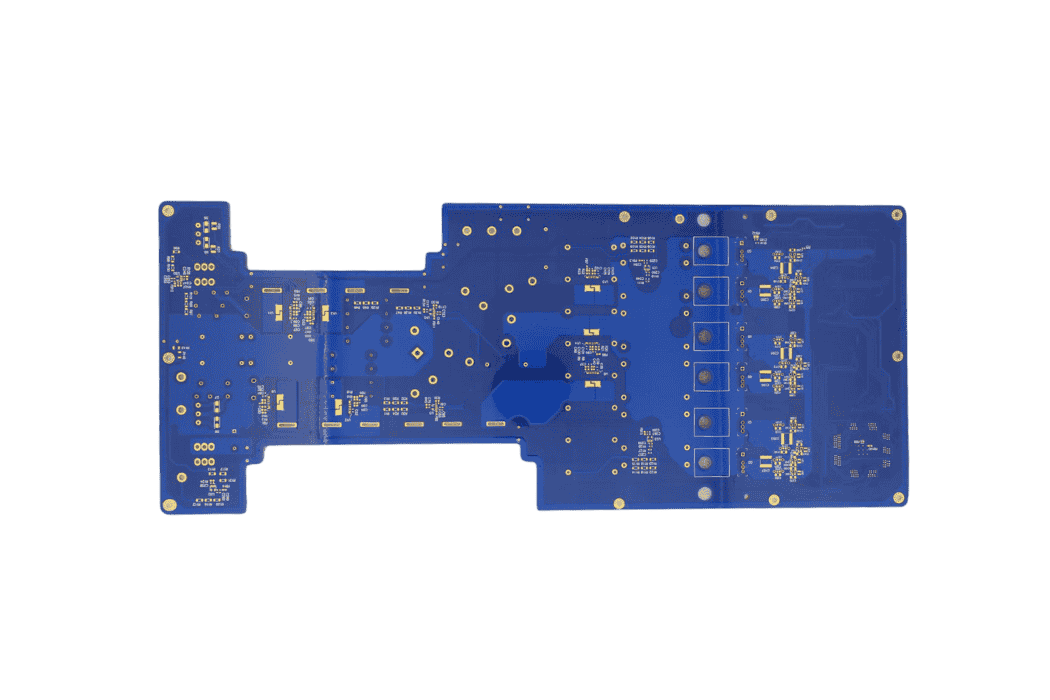

Introduction to Thick Copper PCBs

As the demand for high power products grows, so does the demand for heavy copper PCBs or thick copper PCBs. Rush PCB manufacturers regular PCBs with copper thickness of 1-3 oz (35-105 um). We also make thick copper PCBs with finished copper weight of more than 4 oz. These PCBs have a copper thickness of 140 um.

For all your requirement of thick copper PCBs, come to Rush PCB, the best thick copper PCB manufacturer in the industry.

The industry uses our thick copper PCBs mostly for power electronic equipment such as power supplies. Additional copper weight in the PCB allows it to conduct higher currents without raising the board temperature. Most of our thick copper PCBs are single- or double-sided, although we make them multi-layered as well.

For all your requirements of high-quality thick copper PCBs, contact us today.

Fabricating Thick Copper PCBs

For us, every thick copper PCB is a special PCB. We use special conductive materials, substrate materials, and special production processes that are different from those we use for conventional boards. We use thick copper plating for increasing the copper weight in sidewalls of vias and plated through holes. This helps in reducing layer numbers. Using thick copper plating, we can integrate high currents and control circuits, thereby making high-density boards even with simple board structures.

In regular subtractive manufacturing process, etching thick copper PCBs presents a special problem of undercutting, which makes the cross-section of the copper traces trapezoidal rather than rectangular. To overcome this problem, Rush PCB makes thick copper using the additive manufacturing technique, where we build up the thick copper using a plating process.

Convert your thick copper design into high quality PCBs. Call us today, or visit our quote page.

Advantages of Thick Copper PCBs

Compared to regular PCBs with standard copper thickness, heavy copper PCBs have the following advantages:

- Increased current carrying capacity

- Higher endurance to thermal stress

- Higher heat dissipation

- Higher mechanical strength at PTH holes and connectors

- Possibility of using on-board heatsinks

- Reduced product size

Applications of High Copper PCBs

Manufacturers of high-power electronic products require thick copper boards for solving their thermal efficiency problems. They use thick copper PCBs mainly in automotive electronics and power modules. Rather than using cables and metal sheets for distributing power, these manufacturers depend on high copper PCBs from Rush PCB.

The use of high copper boards not only improves their productivity, but also reduces expensive wiring. This in turn, helps to improve the reliability of the products. Removing wiring from the product also helps in miniaturization of the product.

For applications requiring high cooling, high current, and high power, the thick copper PCB plays an important role. Thick copper PCBs are more expensive compared to regular boards not only on account of the extra copper, but also for their requirement of advanced equipment and professional engineering expertise.

To know more about high copper PCBs, contact us now!