Whether a printed circuit board (PCB) goes inside a water analyzer, a spacecraft, or on an airplane, it is easy to measure the cost of failure—in terms of the number of lives or the number of dollars lost. For these situations, Rush PCB recommends that designers pay special attention to the design choices they are making. This is because high-reliability engineering goes together with good design practices, especially when the PCB must work in a harsh environment.

Quality Versus Reliability

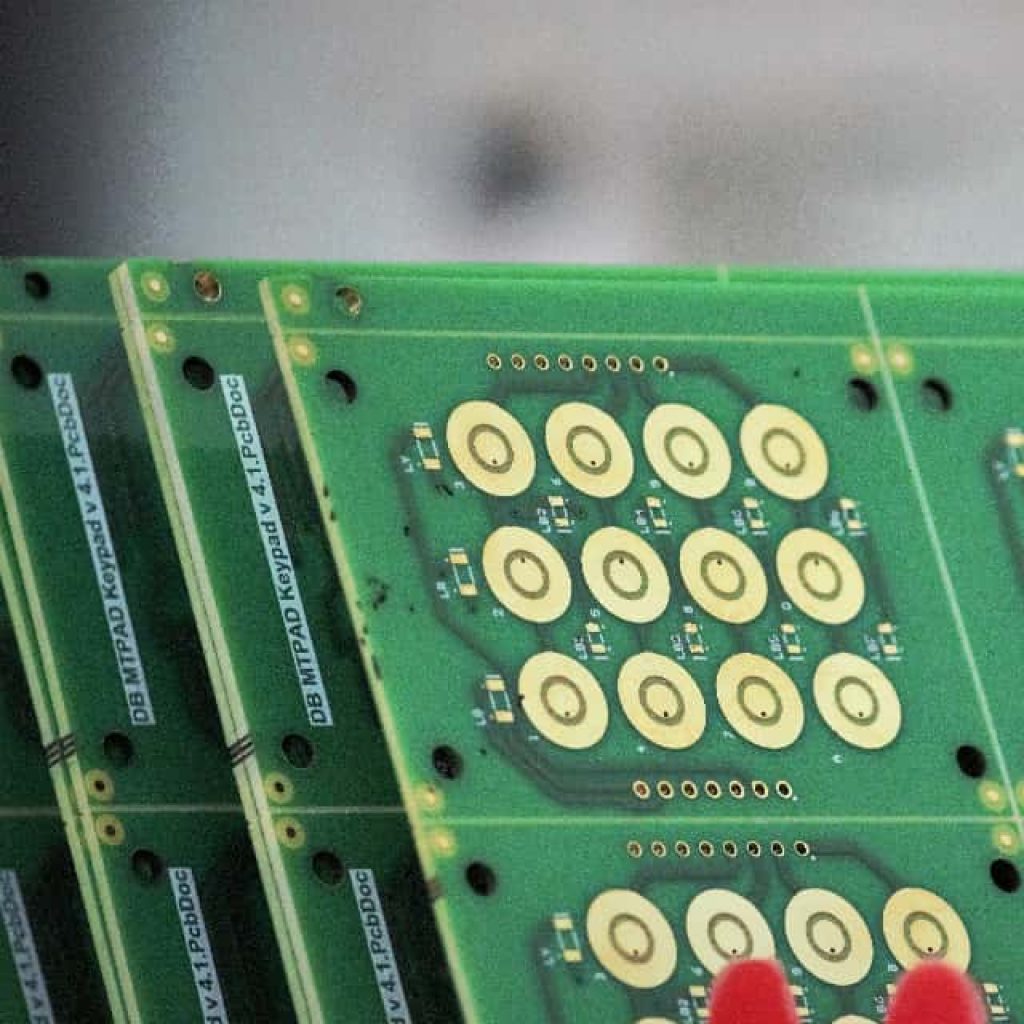

in all probability, an accredited facility has manufactured the PCB, and the manufacturer had assigned an employee the task of ensuring the board will meet or exceed expectations in all design aspects. This may include planarity, surface finish, plating thickness, and so on. As these are all measurable quantities, it is easy to check whether the board has met the requirements, or it has not.

Once the customer has accepted the boards after delivery, the responsibility of the manufacturer for the quality of boards usually comes to an end. At delivery, customers expect all the boards to function as per their design.

Read About: AVOIDING COMMON PCB FAILURE MODES

However, reliability covers the entire life-cycle of the product, and is a much harder metric to quantify. This is because several factors affect reliability, and these include material variability, manufacturing process control, and PCB design. Additionally, board failure dates will vary and are usually unknown.

According to Rush PCB, even if the designer has followed all best practices, the manufacturer has carried out all processes flawlessly, manufactured PCBs usually have slight variations due to material variability. To this variability, if one adds poor process control and or poor design choices, the PCB can contain latent defects.

Unlike quality, which is easy to define—either a board complies with specifications, or it does not—it is not easy to define reliability, since it is difficult to predict whether the PCB will fail within a year, in five years, or after 10 years into its service life. Rush PCB offers a few design tips that will help improve the reliability of PCBs to a large extent.

Maintaining Connectivity

For an electronic equipment to function properly, all electronic components must remain connected to one another. For instance, within ICs, silicon dies must remain connected to metal lead frames with bonding wires. Lead frames must remain connected to copper pads on the PCB with solder, and copper pads must remain connected to each other with vias, copper pours, and traces. In a high-reliability board, all these connections must remain intact over the life-span of the device.

Matching Coefficient of Thermal Expansion

When the temperature of the components or the board itself rises, they expand at different rates, according to the coefficient of thermal expansion (CTE). For PCBs, the CTE is anisotropic, which means the expansion along the length (X- and Y-axis) is not the same as along the width of the PCB (Z-axis). This unequal expansion can crack the barrels of through-hole vias in the PCB, making it inoperative. Therefore, Rush PCB recommends designers use materials with matching CTE, where the expansion of the copper will match the expansion of the PCB material.

Read About: WHAT IS A SOLDER JOINT?

Open and Filled Vias

Open vias near pads may lead to two types of failures. Open vias can capture contaminants such as flux that can slowly corrode the copper over time, leading to a disconnection. The other problem with open vias is they can cause solder thieving. Molten solder from a nearby pad can flow into the via hole, leaving very little solder for a proper bond between the pad and the component. Rush PCB recommends filling the via with either conductive or non-conductive material to prevent such failures.

Thermal Profile

Boards with SMDs go through a soldering process known as reflow soldering, while those with through-hole components undergo wave soldering. For both methods of soldering, it is necessary to find the most optimum thermal profile for the board to follow when it passes through the soldering machine.

For solders with a composition of Lead and Tin, the melting point was low enough to allow the board adequate time to heat up and the solder to flow. However, with the enforcement of the RoHS directives, the electronic industry must use solder with compositions that do not use Lead.

This requirement of removing Lead from solder has brought in solder compositions that have a higher melting temperature. The designer must now use PCB material that can withstand these higher temperatures without damage. Moreover, the thermal profile for the Lead-free solder now must allow the board to attain the higher temperatures necessary, but for a smaller duration.

To comply with the RoHS directives, Rush PCB recommends that assemblers use suitable Lead-free solder and solder paste when assembling boards, and adjust the time and temperature settings in the soldering machine to set a proper thermal profile. The optimum thermal profile should be able to reliably solder the heaviest component on board as well as the smallest.

Conclusion

For making reliable RoHS compatible PCBs for our customers, Rush PCB follows best practices such as Design for Assembly so that the assembly procedure is as smooth as possible. We use the latest machines for assembly and automated testing to give our customers the highest reliability for their PCBs.

Call Rush PCB today, or visit our website for all your PCB requirements and immediate quote.