Our Clients

RushPCB – Your one stop shop for PCB Manufacturing, Prototyping and PCB Assembly in the USA

RUSH PCB is your one-stop shop for all types of PCBs – Printed Circuit Board Manufacturing, PCB Design, PCB Fabrication and Full Turnkey PCB Assemblies in the United States, based in California. We specialize in high layer count PCBs, Engineering Prototypes, and the full range of Electronics Manufacturing Services. Every PCB is built to the highest quality standards, including Rigid PCB, Flex PCB and Rigid-Flex PCB.

All PCB assemblies are built and certified according to ISO 9001:2015, ISO 13485:2016, J-STD-001, IPC-A-610E. Our Electronic Assembly Service is unmatched anywhere in speed, quality, and workmanship. From bare circuit boards to box build and final assembly, RUSH PCB Inc. is your premier one-stop shop, with the most competitive pricing in the industry and a commitment to total customer satisfaction.

EXOTIC PCB MATERIALS

View Details

HDI

CAPABILITIES

View Details

FLEX AND RIGID FLEX

View DetailsMFG CAPABITITIES

View Details

PHOTO

GALLERY

View Details

Get now

Offers & Quotes

INTRODUCTORY OFFER

Free parts upto $500

Get a QuoteEVERYDAY SPECIAL

2 Layer $10 ea/ 4 Layer $25 ea Min 10 pcs

Get a Quote$1500 oFF INTRODUCTORY OFFER

Bare Board

Get a QuotePCB & Assembly

Get a QuoteUPLOAD FILE FOR FLEX AND RIGID FLEX QUOTE

Flex PCB

Get a QuoteRigid Flex PCB

Get a Quote

TURNKEY QUOTE IN MINUTES

– FREE SERVICE

Upload BOM and get components Assy Labor & Bare Boards Prices

*Parts are quoted from Digikey, Mouser, Newark, Arrow & Avent( Authorised Parts Supplier)

Testimonials

Hi Imran, Roy,

Wanted to say thank you for the excellent job on the Board order we received earlier this month. Assembly quality was very high…Fab quality was good…Cleaning was very good, no FOD, no flux residue etc – this has been a big problem recently with other vendors…pleased to see clean boards from Rush. Boards came in on 3/7 as communicated, met my very tight schedule and we delivered to our customer on time. No electrical issues found.

Special shipping instructions were followed to reduce carrier risk.

Looking forward to more orders with Rush, thanks again for the continued partnership.

JULIAN SHUR

SENIOR ENGINEERING MANAGER

Imran, That sounds great, we have some parts that we will be sending early next week. no need to requote, just invoice us accordingly. The 5 CCA’s we received last week looked really good, thank you!!

You guys are top shelf, no doubt!!

Hey Imran, I’m going to be moving on here from Tutamen, and just wanted to send you a little note. Looking back, I’ve been down here in VA Beach for eight years now. You and your team have been a key part of success in my career. I can’t thank you enough for going above and beyond in many circumstances, and being patient with us through the growing pains of maturing our ordering process. My personal thanks to everyone at Rush, and I hope that we’ll be able to do business again soon.

Derek has already started to take lead on many of the orders at Tutamen, and I’ve made every effort to hand over the reins to him to ensure a smooth transition after I leave on the 27th. Best wishes to everyone at Rush for the future!

TIM

Roy,

Thank you so much for all your help here. The skills and expertise of your team are invaluable as we troubleshoot this early prototype design into a product. As I’m sure Meng has told you we are looking to a forecast quite soon in the thousands+ of product to support our first customers. I will follow along closely and would love to get the opportunity to come down and grab a coffee to see the shop. Thank you once again.

Guy

Hi Everyone, I just wanted to thank you for getting these to me prior to 9/28 and for another great job completed with great quality. Thanks again.

Best Regards,

Baruch Spence

Principal Engineer

Thank you. I would like to greenlight these specific boards by Monday so the sooner I can get a quote, the better. Please provide ANY alternative suggestions to out current BOM that you feel will suffice with production. I greatly appreciate the professionalism that you guys have shown me during this process, I look forward to doing business with you.

Patrick Pastures

Buyer

Dear Roy,

I would like to thank you for engaging Ricky, and the rest of your team so quickly. They have been highly responsive and true problem solving partners in getting us closer towards the deadlines and yields that we needed. CC, Dr Miller, our founders and CEO.

Meng

I checked with engineering and they did confirm that it is the 8 kA – However, they say it will work, so it is ok to use the B72220S0271K101.

Thank you again for finding these discrepancies! That is one of the reasons we choose Rush to do our assembly!

Lois

Hi Imran,

Picked up the boards today. They look great. Is there a receipt that we can get for our accounting?

Thanks,

Jerry

Thanks Imran!

This is an incredible bulk of information and I watched the testimonial. I’ll reach back out again once we are closer on layout but no doubt on team’s capability to handle our board. Your capabilities make our board look too easy.

Alex Krause

Director of Hardware

Hello – I was off yesterday so I apologize for any delays. In general everything should be treated similar to the last job you did for us, but I understand and appreciate your explicit level of detail here. Please see by comments updated below in RED.

Rich W.

Senior Design Engineer

Hi Rush PCB, I don’t reach out much after receiving product, I also don’t receive much feedback when we ship out our designs to customers, but I just wanted to let you know I am one happy customer!!! The packaging was excellent, product is outstanding, and the quality measures you presented are such a great guarantee. Solder sample, cross section etc., all of these take time and am glad to see you have a quality assurance program that far surpasses most! It was also extremely easy to work with your team! THANKS FOR SUCH A QUALITY PRODUCT!! Thanks,

Derek Biggs

Engineering Manager

Ron and Rush PCB team,

Back in April, the Rush Team produced two different versions of 4-layer Flex PCB prototypes for us (60 rapid turn prototypes in all).

The quality was EXCELLENT, and better than two other vendors who simultaneously produced the same project files for us.

We have an updated version of the Flex Circuit we need to produce again, and want to place this business exclusively with RUSH, given your successful track record for us.

Thank you in advance, we look forward to this next order.

Bear,

Chief Innovation Instigator

About Us

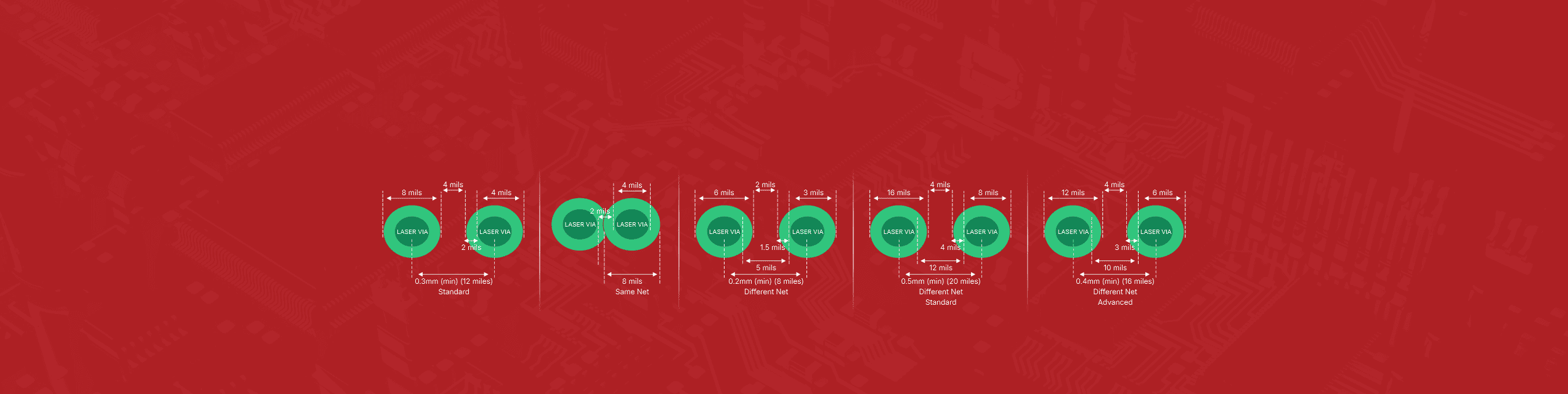

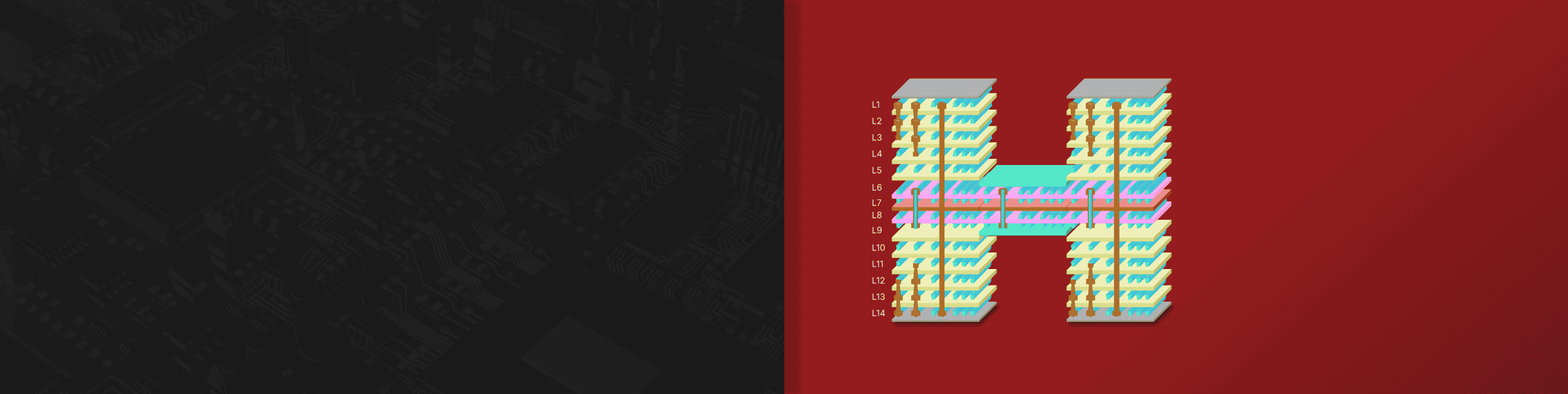

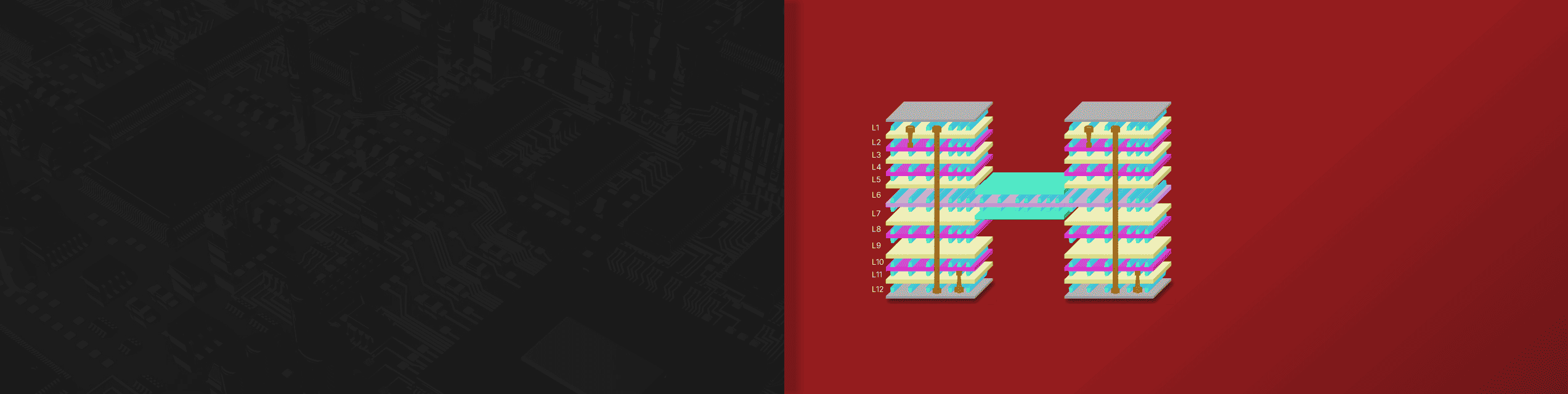

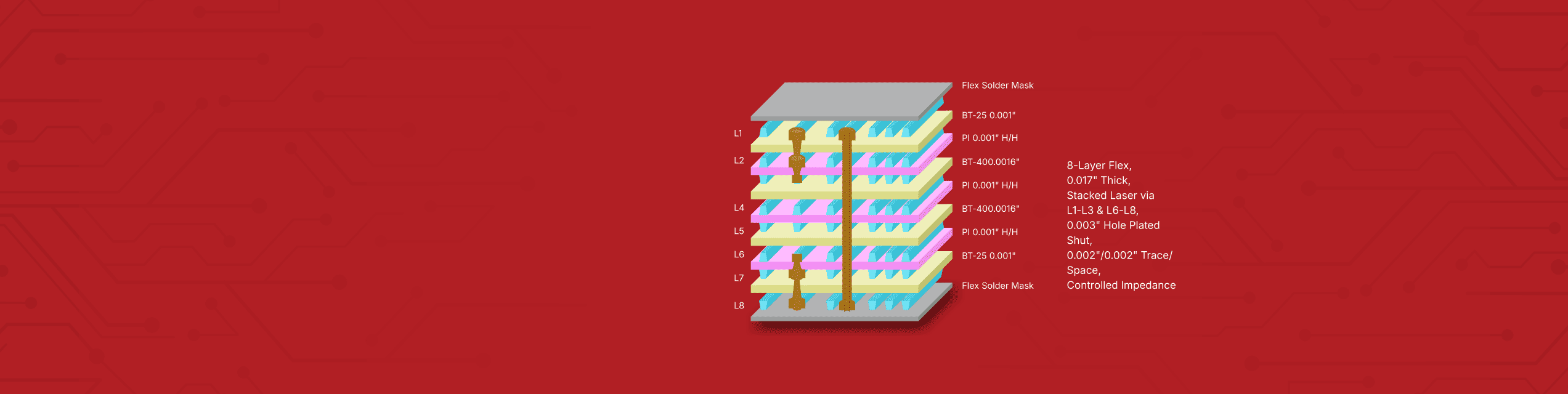

RUSH PCB Inc. specializes in higher layer count PCBs, exotic

materials, laser drill micro-vias, blind/buried vias, as

well as conductive and non-conductive via fill.

Our staff engineers work with you, our customer, throughout

the initial design and development process to ensure

manufacturability, product quality, and consistency.

PCB Manufacturing

Pcb design

testing

Frequently Asked Questions

01.

What services do you offer?

Three basic Printed Circuit Board assembly services are offered by RushPCB Inc:

• PCB Fabrication

• Consigned PCB Assembly

• Full Turnkey Service.

At RushPCB Inc, we can run just a few boards, built up quickly, with flexibility in kitting the components.

At RushPCB Inc, we are optimized for runs of up to 5,000 boards, this is our Production Assembly Service. Priced right, this is perfect for taking your finished design to market. When you have completed testing of your design, and are ready to start building your product in quantity, choose this product.

To see detailed benefits and requirements for each of our assembly services, please visit our Services Overview page, or call RushPCB Inc. at 408-496-6013 or email us at [email protected] for more information.

02.

What are the requirements for service?

The requirements of RushPCB Inc. assembly services, We are very flexible regarding services required by the customer – with little to no restrictions on PCBs, Parts, or Placements

- PCBs:

- 500in X 0.500in (min)

- X 23in. (max)

- Parts:

- Cut & Continuous tape – Min 6” Cut tape required.

- Full or Partial Reels

- Tubes

- Trays

- Thru-Hole parts on tape or in bulk

- Placements: N/A

- Data:

- Gerber CAD Data with NC Excellon Drill file (ASCII format)

- Bill of Materials (.xls, .xlsx, .csv, or tab-delimited text)

- RS-274X Gerber files

- Centroid (aka Pick-and-Place) file

03.

What data (files) do you require for assembly orders?

Depending on the assembly service you are using, RushPCB Inc. requires some or all of the following information:

• Gerber CAD Data with NC Excellon Drill file (ASCII format)

• Bill of Materials (.xls, .xlsx, .csv, or tab-delimited text)

• RS-274X Gerber files

• Centroid (aka Pick-and-Place) file

04.

What are your technical capabilities? / What can you assemble?

You will find many of our standard capabilities here, but RushPCB Inc. takes pride on being able to handle almost any job.

If you can’t find what you need here, call us at 1-408-496-6013 or email [email protected] with your job specs, and we’ll see what we can do to help.

05.

Can RushPCB Inc order my parts?

Absolutely. If needed, RushPCB Inc provides Turn-Key service. We can order your parts, manufacturer Printed Circuit Boards, assemble the PCBs, test them, and provide the completed PCBs to you.

To see detailed benefits and requirements for each of our assembly services, please visit our Services Overview, or call RushPCB Inc. at 1-408-496-6013 for more information.

Our Blog

Read our latest blog

Rogers vs. FR4 PCB Materials: Which is Right for Your High-Frequency Applications

Introduction PCBs or printed circuit boards must be made from the right materials to deliver the performance expected of them. The proper choice of materials for a PCB not only affects its final quality and cost but also its functionality and performance. Among the many types of materials available for manufacturing PCBs, two are most commonly used. These are FR4

How to Choose the Right SMD Component Package Size for Your PCB Design

Introduction There are innumerable types of packages available for SMD components, which complicates the choice for the designer as to the specific size that would be the most suitable for their design. In this article, we, at Rush PCB Inc., will address this issue. We will discuss the several types of packages and the reason for their existence. We will

Flex Cut vs. Non-Flex Cut PCBs – Key Differences and Applications in Modern Electronics

Introduction Many modern electronic appliances nowadays use flexible circuit boards as these offer several advantages over the regular rigid variety. High-precision lasers or other mechanical tools that perform precise cutting operations on flexible circuit board materials are referred to as flex cuts. A high-precision cutting technology utilizes precision lasers or mechanical tools to create complex shapes or small sizes of