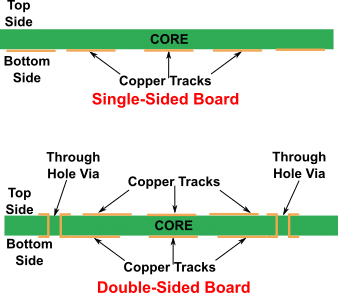

Rush PCB Inc makes all types of printed circuit boards or PCBs starting from single and multilayer boards and including double-sided boards as well. Single-sided boards usually have a substrate bonded with a layer of copper foil on one side, whereas in double-sided boards, the substrate is sandwiched between two layers of copper foil bonded on both sides. The substrate with two copper foils is also known as a copper-clad.

Why Two or More Layers are Necessary?

Whether the circuit uses through-hole components or surface mount components, it is always possible for a single layer board to completely contain it. If the circuit is complicated, a few wire jumpers may be necessary to accommodate it. However, with a single-sided PCB, the size of the board may become too large.

With electronics regularly shrinking in form and size, a large PCB can become a handicap. Adding another layer to make a double-sided board is like folding a single-sided one itself. This effectively halves the size of the board while still accommodating the entire circuit. However, both single and double-sided boards have their advantages and disadvantages.

Advantages of Using a Single-sided Board

- Simple to design

- Simple process of fabrication

- Easy to assemble

- Assembly time is lower

- Easy to troubleshoot

Disadvantages of Using a Single-sided boards

- Large size for complicated circuits

- Low component density

- Low mechanical strength

- Unable to withstand high levels of vibration

Advantages of Using a Double-sided board

- Higher component density with vias

- Can support complicated circuitry

- Possibility of hybrid assembly

- Smaller size for complicated circuitry

- Higher mechanical strength

- Can withstand higher levels of vibration

Disadvantages of Using a Double-sided Board

- Design time required is higher

- Fabrication processes are more complicated

- Takes longer to assemble

- Troubleshooting is more difficult

When to Use Single or Double-sided Boards?

The industry prefers single-sided boards on account of their simplicity and low cost. If the space inside the device is ample, a single-sided board may work out cheaper to fabricate and assemble. Because of their simple design, the lead-time for fabricating single-sided boards is smaller, leading to shorter delivery times and a shorter time to market.

However, when the circuit is complicated and has a large number of components, the space inside the device may not be able house a large single-sided board. In such cases, a double-sided or even a multilayer board may be necessary.

It is possible to use both through hole components and surface mount components on both types of PCBs. For through hole components, the PCB must have holes to accommodate the long leads. For a single-sided board, the connections for through hole components are available on the bottom side of the board. On the other hand, for surface mount components, a single-sided board will have connections on the top side.

When using through hole components on a double-sided board, the bottom layer provides the connections. However, the top side may also have additional connections, with through hole vias connecting the two layers. For a double-sided PCB, it is possible to mount surface mount components on both sides.

Another advantage of single- and double-sided board is they support hybrid assembly. Therefore, it is possible to use a mix of through hole components and surface mount components on the same board. While through hole component mounting is possible only from the top side of the board, there are no restrictions in mounting surface mount components—it is possible to mount surface mount components on top, bottom, or both sides of the double sided board. However, for a single-sided board mounting surface mount components is possible only on the bottom side.

Conclusion

Two factors majorly govern the use of single- or double-sided boards. One is the size, and the other is the cost. According to Rush PCB Inc, although the design and construction of single-sided boards is simpler, the larger size necessary to accommodate the entire circuit can offset the cost. For space constrained designs, the double-sided board may work out cheaper, even when the design and construction are more complicated.