Rush PCB Inc offers specialized PCB assembly services for prototyping, small-volume, and large-volume production. This makes us a unique one-stop destination for fabrication and assembly of boards. Our arrangement not only makes your R&D work to be easier, but also helps you realize your long-term goals while saving time-to-market. We have professional engineers and technicians who will work closely with your team to ensure you receive the best quality and the quickest possible lead time. Rush PCB fulfills thousands of orders from around the world, and this has established us as the leading supplier of PCBs and PCB assembly services because of our consistent quality and excellent services.

Difference Between PCB Fabrication & PCB Assembly

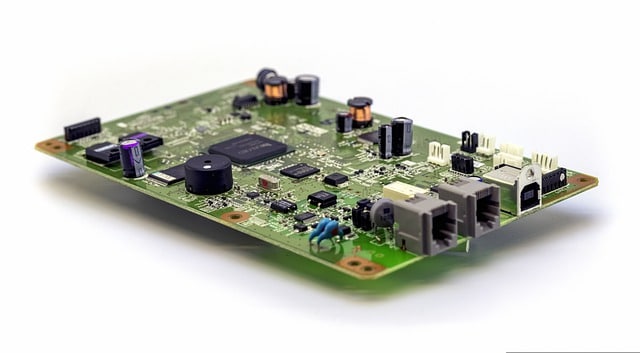

PCB fabrication is the process of manufacturing the bare printed circuit board. We use the bare printed circuit board for the assembly process, using additional electronic components. For PCB assembly, we offer turnkey PCB assembly services. We also accept consignment kits. In turnkey PCB assembly, we fabricate the bare PCB, procure the components, and provide the assembly labor. We also accept consignment components from customers, provided they meet our overage guidelines. We also provide bare board panelization Services to our customers.

What is PCB Assembly?

Assembling a printed circuit board requires soldering electronic components on the bare board. We can install both SMT or surface mount and THT or through hole components on the bare board. If the assembly requires both types of components at the same time, it becomes a mixed assembly.

Rush PCB Assembly Capabilities

We offer various types of assembly capabilities for our customers. These include:

- Surface Mount Technology (SMT) Assembly

- Through-Hole Technology (THT) Assembly

- Ball Grid Array (BGA) Assembly

- Mixed (SMT+THT) Assembly

- Rigid-Flex PCB Assembly

- Flex PCB Assembly

- Leaded Solder Assembly

- RoHS Solder Assembly

- Selective Assembly

Our PCBs and PCBAs are compliant with a wide range of standards, including IPC 610 Class 2 and Class 3.

Rush PCB Assembly Services

Starting from prototyping to large-volume production, Rush PCB offers a broad range of printed circuit board manufacturing and assembly services. Our PCB assembly services include:

- Prototyping Services

- New Product Introduction Services

- Supply Chain Management

- Assembling a wide range of printed circuit boards

- BGA Reworking

- Conformal Coating

- Automated Optical Inspection

- X-Ray Inspection

- In-Circuit Testing

- Flying Probe Testing

Rush PCB Supply Chain Management Services

To make it easier for our customers, Rush PCB also offers several types of supply chain management services. These include:

- Quickturn Prototype Services

- Full Turnkey Services

- Semi-Turnkey Material Handling Services

- Consignment Services

- Large Volume Production Services

Our quickturn prototype services allow your R&D to evaluate their design quickly. We also help in the design process with our DFA and DFM services. This not only helps you finalize your design quickly, but also reduces your time-to-market, thereby helping you beat the competition.

We help our customers offload their entire procurement and assembly activities through our full turnkey services. You do not have to search for components, order them, follow up with deliveries, and handle obsolescence—Rush PCB handles all this for you. We have links to major component distributors, and we can help with the logistics of procurement and supply.

As we buy components in bulk, we can also offer price discounts. You do not have to qualify suppliers, as we already have a list of qualified suppliers. You do not have to maintain an inventory, as we are already doing that for you. Not only do we manufacture your bare board, we also procure all your components on time, and we supply the labor for assembling them, inspect the assembly, and test it for functionality.

However, some customers may want to procure key components themselves. We have semi-turnkey material handling services for such customers. We accept a part of the BOM that the customer offers, and we arrange for the procurement of the balance components. We then proceed to assemble the components on the PCB, inspect the assembly, and test it for functionality before delivery.

Rush PCB also accepts consignments of multiple board assemblies. The customer may offer us consignment kits of components for different board assemblies. We assemble such consignments with multiple assembly lines running in parallelly. Our state-of-the-art machines and tools are way ahead of our competitors, and we offer the best quality workmanship in the industry.

With our modern machinery, we also offer our customers large-scale production services. We maintain a complete inventory for all parts, including manufacturing of the bare board. Our statistical quality control processes ensure consistent quality and reliability of all products we fabricate and assemble.

Why Rush PCB for PCB Assembly?

If you have any requirement for fabrication of printed circuit boards and assembling them, you will find the single-window solution offered by Rush PCB the most economical in terms of quality, cost, and time. Our state-of-the-art machinery and well-qualified personnel guarantee that you will get the best quality, workmanship, and reliability for all your products we manufacture and assemble for you.

You can obtain a PCB & PCB-Assembly or Full Turnkey quote by emailing us your Gerbers & BOM for RFQ.

To contact our PCBA team or request more information about PCB services, please email us at [email protected] or call us at 1-408-496-6013.