Parts Shortage – PCB

While assembling SMT PCBs for a customer, the line unexpectedly ran out of 01005 package size resistors during the production run. This was due to an error on the customer’s part; they simply did not provide us with enough. But the customer still expected the finished product in-hand by the due date, and we did not want to disappoint him.

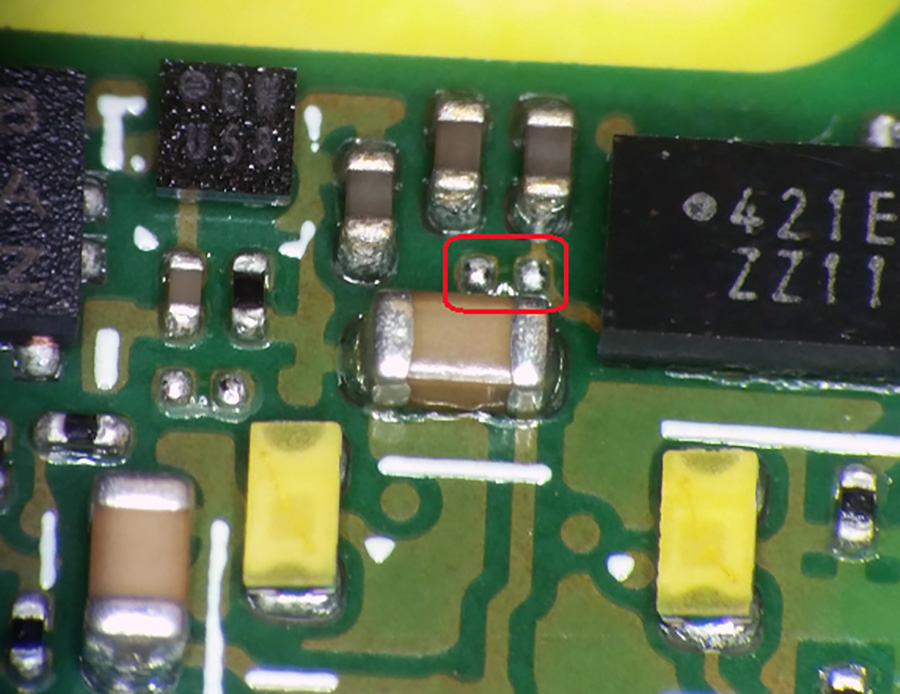

This, of course, created a dilemma. Should we halt production while additional parts were ordered, or simply continue? We placed a replenishment order immediately, and learned that we could not get them until the next day. We asked, “Is it possible to assemble these boards now, and add the part later when they arrive?” We also had to quickly assess the feasibility adding the part later on. How accessible is the site for this tiny part? Can it be done by a skilled soldering technician? We decided that it could.

We proceeded to build the order with the exception of that single 01005 component. The site was accessible, we decided, so that the part could indeed be added individually to each PCB. Sure, it would take some time and hand soldering, but it would not cost us nearly as much time as if we had put the entire build on hold to wait for the parts.

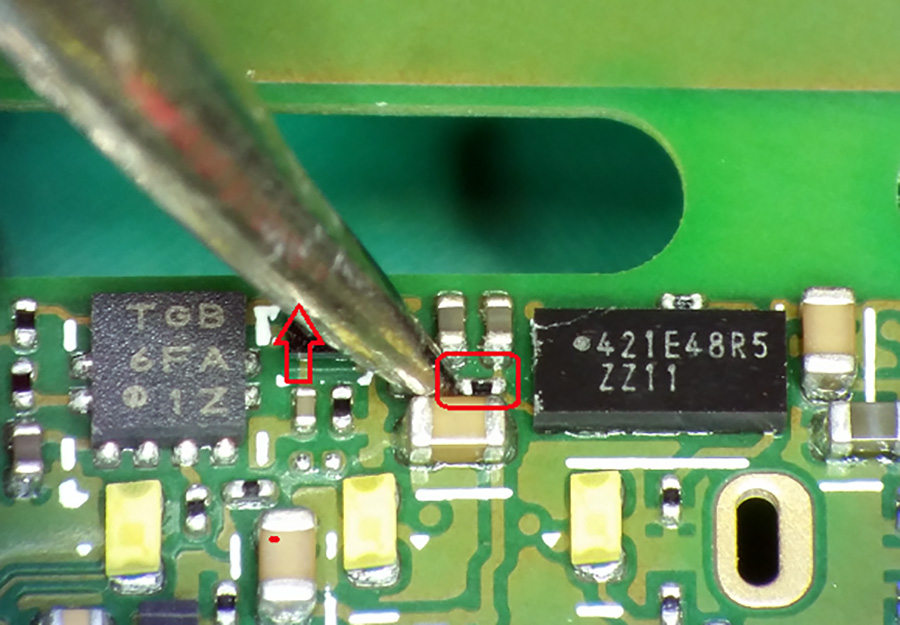

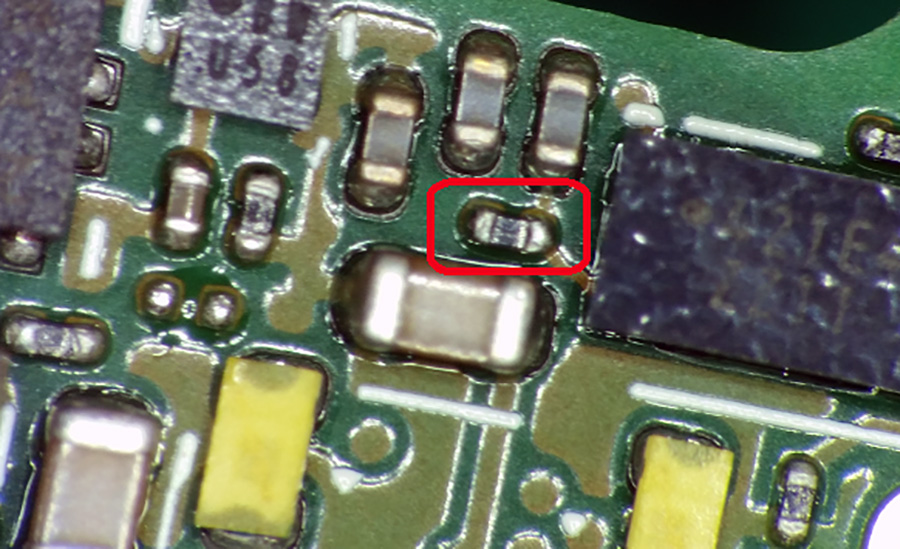

Once the needed parts arrived, they were hand soldered onto each assembly by a skilled operator using slender soldering iron tips.

When the parts arrived the next day, we were able to employ our best hand soldering people with soldering irons equipped with special slender tips. The job went quickly and easily, and we were able to minimize downtime on the SMT line due to the unexpected component shortage, and keep this job on schedule, much to the relief of our customer. We came through for them despite their mistake, and they appreciated that.

The 01005 parts were easily and quickly added, and the entire job shipped by the required due date since the rest of the assembly had already been finished.

Efficient use of time, getting whatever can be done while minimizing down time, pays dividends when one is living by tight delivery schedules and expected ship dates. The more that can be achieved without unnecessary delays, the better the chances that a ship date can be honored.