As PCB designers, fabricators, and assemblers, we wear a lot of hats here at RUSH PCB. We’re always working to design and build PCBAs that are the best that they can be. But sometimes we are consigned product to assemble that wasn’t designed by our team, and every once in a while, we will get boards to assemble where we’re temped to say that “The designer clearly wasn’t thinking about how we are going to build this!” Design for Manufacturing (DFM) principles really are critical and can make the difference between an assembly that is easy to build and one that is nearly impossible. As SMT/PCBs become ever more compact, and components are large, or odd-form, designers need to take into account the special needs and limitation of the automated assembly equipment in the work stations, because few if any assemblies can be cost-effectively assembled by hand. It’s always important for PCBA designers to talk to the manufacturing engineers at the assembly house where the parts will be consigned! Working together saves a million headaches.

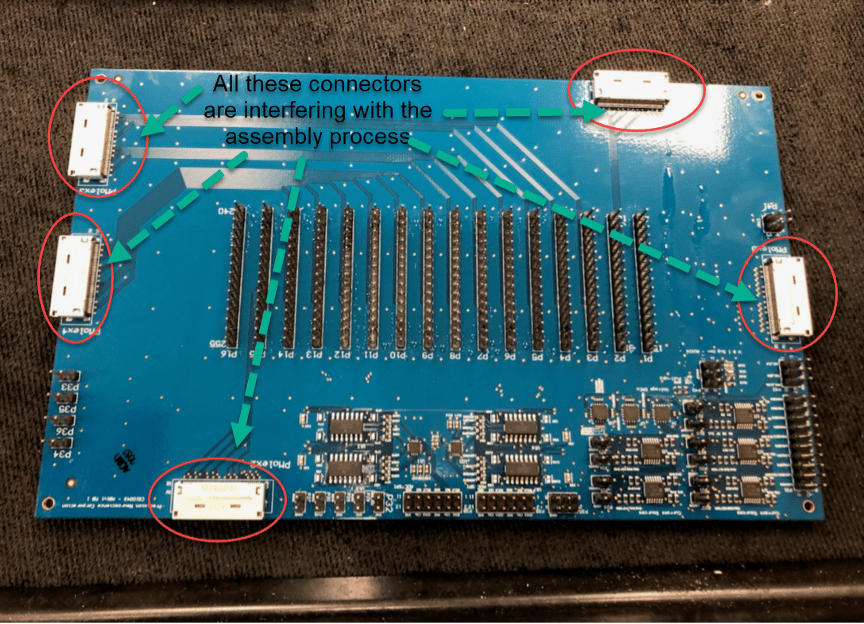

In one instance, as an example, we were consigned to build a PCB assembly that, we learned upon examination, had zero edge clearance. How is that possible? The assembly has 5 edge mount connectors (PMolex1 through 5), which extend out from the board approximately 1.5mm on each of the 4 sides of the board. But all of the equipment that we use to assemble our products, which must be capable of holding the PC board by at least two (2) of its edges, requires a clearance of approximately 5 – 10 mm. As a result, these PCB assemblies have effectively zero edge clearance, as shown in Figure 1, where the interference caused by the connectors is obvious.

Figure 1: Processing the PCBA is impossible with large connectors in the way. Processing equipment requires appropriate edge clearances!

As a result of this design oversight, the assembly process is very difficult (if not impossible) because we cannot hold the PCBA properly, and some of the connectors actually contact or ‘bump’ the reflow conveyor. That’s unacceptable because it can result in component misalignment or open solder joints, requiring costly rework and delaying shipping deadlines. Not leaving enough clearance is a design oversight that can have costly consequences.

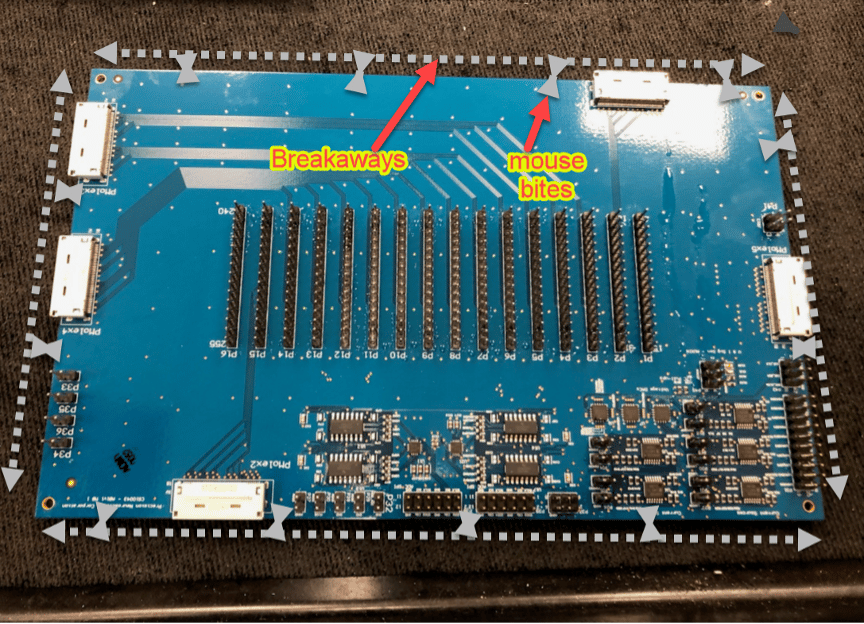

Mission Impossible? Not really, because in this case, there is a great solution, and also a not-so-great one. In the first and best solution, 10mm wide breakaways can be added all around the edges of the board. The breakaways are connected to the board with 2.5 to 3mm long ‘mouse bites’. This solution, shown in Figure 2, will speed up the assembly the process, protect the connectors, and prevent the need for rework due to misalignments or open solder joints.

Figure 2: Breakaways and ‘mouse bites’ to hold them in place provide an ingenious solution that eliminates the need for fixturing and potential rework while providing needed edge clearance.

The less-than-desirable solution would be to ask the customer to pay for fixtures to accommodate the PCBAs for passage through the pick and place, reflow, and AOI inspection systems. Clearly, the first solution described would be the better of the two since it is lower in cost than fixturing