Introduction to High-Tg PCBs

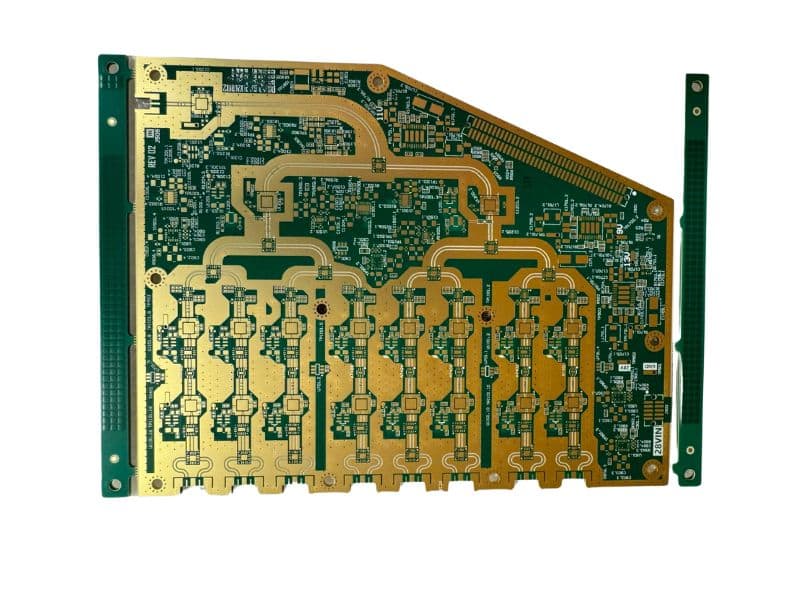

Among High-Tg PCB manufacturers, Rush PCB is a name of repute. We make all types of PCBs, but high-Tg PCBs are our specialty. Right now, there is a great demand for boards with high Tg value and this is due to the advancements in electronic technology for applications involving high temperatures. Tg or glass transition temperature is one of the most important properties of any epoxy material, denoting the temperature region where the base material, either glass or polymer, changes from its glassy, solid, and rigid form to a soft and plastic form.

Depending on its composition, each PCB substrate will have its own temperature beyond which the material will start becoming soft. If the operational temperature during PCB fabrication crosses the Tg value of the material, it will become difficult to fabricate the board. Therefore, PCB manufacturers typically look for high Tg material for the substrate. Boards made of material with high Tg value have a better stability as the substrate has higher heat resistance, which also improves the mechanical and chemical stability of the board.

Rush PCB recommends using materials with Tg value at least 25-30 degrees higher than the temperature during the fabrication and operation of the board. For instance, the industry can use a PCB with a rated Tg value of 150 °C only for applications that remain below 125 °C.

Please get in touch with us for all your high-Tg PCB requirements.

What are High-Tg PCBs

Beyond Tg, or the glass transition temperature, the base material of a board, whether polymer or glass, ceases to maintain its sold and rigid nature, and starts to change over into a plastic or rubbery state. This is a mechanical change and the highest temperature at which the material maintains its solid and rigid nature is the glass transition temperature commonly denoted as Tg. Beyond the glass transition temperature, the PCB substrate not only becomes soft, it deforms and melts. Simultaneously, there is a sharp decline in its electrical and mechanical properties. These can affect the life of the product.

For PCBs made of regular FR-4, the Tg is between 130-140 °C. Materials with medium Tg can withstand up to 150-160 °C. Materials with high Tg are those that can withstand temperatures of 170 °C and beyond.

Materials with high Tg values also exhibit better mechanical properties and higher chemical resistance as compared to standard FR-4 material. Additionally, higher the Tg value, better is the temperature withstanding capability of the material. Modern electronic equipment do not use hazardous substances as specified by RoHS and WEEE. During assembly, lead-free processes use a higher temperature than regular leaded processes do. Therefore, materials with higher Tg value are more in demand.

We offer the best high-Tg boards in the industry. Contact or call us today.

Advantages of High-Tg PCBs

High-Tg PCBs have many advantages:

- Capability to withstand high temperature without damage

- Capability to withstand higher thermal stress

- Low thermal expansion

- Good mechanical properties

- Highly durable

- Excellent PTH reliability

- Longer time to delaminate

- Call us today to discuss your project. We will convert your high-Tg designs into reality.

- Applications of High-Tg PCBs

The electronic industry widely uses high-Tg PCBs made by Rush PCB. Some of the industries include:

- PLC manufacturers

- Wi-Fi manufacturers

- Embedded system development

- Computer manufacturers

- Power supply manufacturers

- Inverter manufacturers

For more information on high-Tg PCBs, contact us today.