Flex capability, material selection, process tolerances, manufacturing logistics, and your flex supplier all play an important role in producing a cost-effective and reliable flex circuit design.

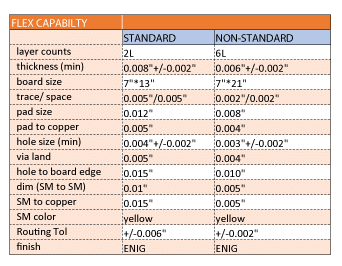

At Rush PCB Inc will assist you in design for PCB manufacturing to minimize overall program costs. Listed are standard materials and capabilities.

Come speak with us should your design require tighter tolerances or special process treatments.

Flex Manufacturing Capabilities

In PCB manufacturing of flex capability, PCB Company creates bare boards. For the past ten years and more, this has been the core of our business or flex capability.