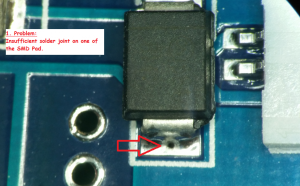

1. Problem: Insufficient solder, i.e., ‘Starved’ solder joint on one of the SMD pads.

In the first close-up photo of a PCB assembly, It seems as though solder has flowed ‘down the drain’ and away from the solder joint where it’s needed; and in fact it has, because the customer has inconveniently located a via right through the center of one of the two top-side SMT pads for a surface mount component. When the assembly PCB is run through reflow, the molten solder drains away through the barrel of the via and out the other side of the PCB board. There isn’t enough solder remaining post-reflow to create an acceptable solder joint per IPC-A-610. The joint is ‘starved’; this is unacceptable. What to do?

The via is there to stay, by virtue of the customer’s design. So, no matter how many times you add solder to the joint, every time you run the PCB through the reflow oven, the solder is going to drain away because the PCB , including the via, is at reflow temperature.

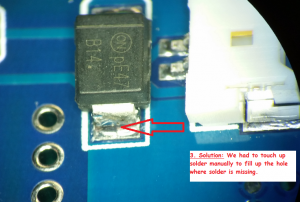

Obvious, more than one run through the oven makes no sense. The only practical solution, which we implemented here at RUSH PCB Inc., is to manually add solder to the individual solder joint, post-reflow, without running the entire PCB through another thermal cycle. It’s a touch-up procedure that’s require, to create a robust SMT solder joint that meets acceptability criteria. It is a manual PCB assembly soldering process that will perform by a skill hand-soldering or rework operator. Solder is only add to the joint, via cored wire solder or solid wire with flux, in order to build up the volume of solder at the solder joint to provide strength, connectivity, and an acceptable meniscus per IPC standards, covering the via drain-hole. The solder won’t flow through the via because only the surface joint area is being heated.

2. Solution: Solder add to the joint manually, via a ‘touch-up’ procedure,

It may seem tedious, but a skilled operator can accomplish the touch-up job in only a few seconds, and if there is only one instance per assembly, it won’t appreciably cause production delays.

Roy Akber, CEO, RUSH PCB Inc.