Innovative Solution for Soldering Challenge in Double-Sided SMT PCBs

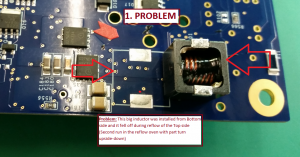

Double-sided SMT PCBs are usually no problem to solder; two passes, and the bottom-side components are held in place with SMA adhesive. But occasionally, a large or heavy component on the bottom side, such as an inductor, poses a problem because it will drop off during top-side reflow. In one particular case, an inductor with an open bottom (with inner coils visible) couldn’t be fixed in place with adhesive. Its two pads didn’t have enough solder surface tension when liquidus to hold it to the bottom side of the board during the board’s second run in the reflow oven with part turned upside-down. What to do?

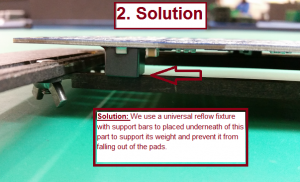

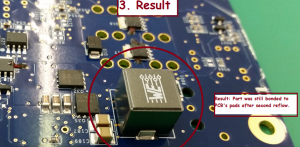

The solution was a universal reflow fixture with support bars, located beneath the part to support its weight during reflow so that it would not pull loose and drop. The fixture had to hold it firmly in place and in location during the second pass through the oven.

Other solutions were either unsuitable or added an extra process step. The use of adhesive, as mentioned above, was not practical, since there was little available component body to attach to, and one did not want any foreign material, i.e. adhesive, to get inside the component body with the exposed coils. Nor was the use of a higher-temperature solder practical; the component is a standard part and simply needed to install with the other components without additional steps or complications.

Adapting the universal fixture to hold the inductor in place was an easy matter. The flexibility of universal fixtures is such that they can be adapted to support a wide variety of component sizes and shapes effectively across a wide range of board sizes, layouts, etc. They are also much less expensive than a custom fixture, and readily available for use. Consider this in contrast to an expensive custom fixture that will require on average 2 – 5 days to fabricate.

The universal fixturing will do the job, and be re-usable; it’s a one-time investment that can be used over and over again for a multitude of different assemblies. Saving production time and tooling costs has a positive effect on profitability, and at the same time, the highest level of product quality and reliability is maintained. Obviously, not all assemblies require fixturing, only those with special requirements like this one that cannot be processed as simply as most SMT assemblies can.

Roy Akber

CEO

RUSH PCB Inc