Ball Grid Array (BGA) Rework

Occasionally, BGA assemblies require modification, or rework. Rush PCB has the know-how and experience with BGAs to do it right and preserve your assembly’s robust reliability.

Reworking and/or Replacing a BGA

When reworking the solder connections underneath the BGA, the solder needs to be heated for reflow, without damaging the PCB itself or the other components on the board. This involves sending the heat to melt the solder through the BGA.

However, so that the PCB is not thermally shocked, the rework process begins with preheating the circuit board. Once the PCB itself has preheated, just enough extra heat is applied to the BGA to flow the solder underneath it, and then the BGA is removed from the PCB.

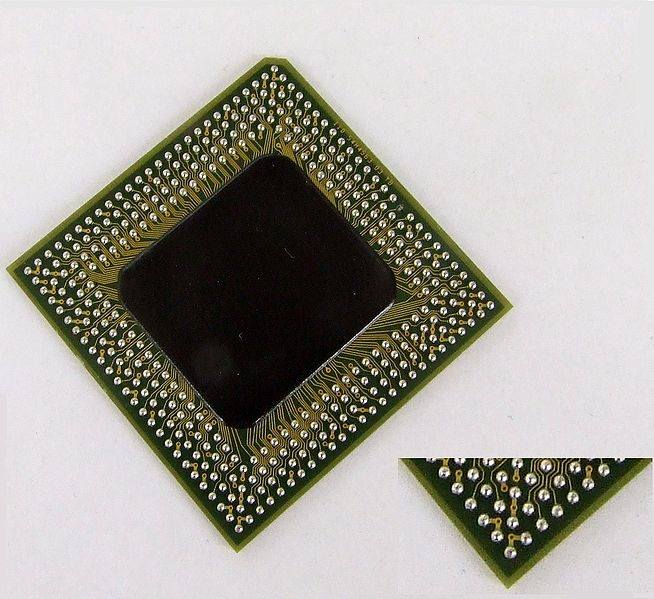

If the BGA is to be reuse, it has to be reballed; the old solder is removed, and then new balls or spheres are attached to the BGA.

The newly reballed BGA is placed onto the PCB assembly. The PCB is preheated again, and once the PCB is up to temperature, the BGA is given extra heated; reflowing the solder and forming new connections.

Only after the reworked printed circuit board is cleaned and inspected is it ready for shipment.

For more information on Ball Grid Array rework, contact us at [email protected] or call 1-408-496-6013.