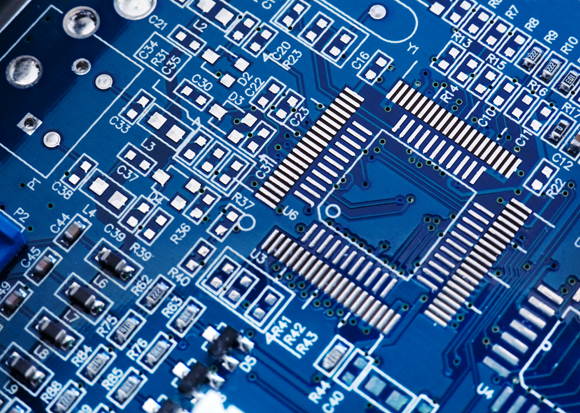

High Current carrying Printed Circuit Boards require heavy copper or high thermally conductive dielectric. Before determining the copper weight, it is advisable to determine allow amount of Heat Dissipation.

IPC-2221A, section 6.2 is a good place to start.

Consideration 1: IPC-2152, Standard for Determining Current-Carrying Capacity in Printed Board Design. Consideration 2: Be generous with your circuit air gap. Your board manufacturer will need sufficient space between conductors for prepreg to fully flow and fill. Work closely with your PCB manufacturer for best material-level performance/price/availability combination.

For high current PCB, besides using heavy copper, you can also use high thermally conductive dielectric, such as Arlon 92ML, which provides 2.0W-m/k (FR4 only 0.26W-m/k thermally conductivity). This will improve the power handling capacity, eliminating use of high copper for improved manufacturability.