Rush PCB offers the first article assembly of PCBs at the most cost-effective rates compared to that from any other turnkey PCB assembly house. First article assembly and approval by the client represent the most significant steps for the successful layout design of a PCB. Approval of the first article circuit board answers almost all queries related to its fabrication, assembly, and testing. Rush PCB provides the first article assembly for boards of different technologies.

First Article Assembly Service

Rush PCB offers the first article assembly service for the benefit of our customers. In this service, we offer the most suitable cost structure for the prototype. We have experienced staff who use their extensive knowledge to offer clients necessary ideas and suggestions on design, thereby improving the manufacturing process and reducing costs so that the process proceeds comfortably towards the placement of order.

Why First Article Assembly?

For every PCB, the first article assembly process is a highly significant step. Any small error in machine setup can lead to multiplication of the error when circuit boards are fabricated in a current work order. Hence it is necessary to use stringent quality inspection techniques for assembling the first article. We train our engineers to fabricate a PCB providing evidence of concept validation. Our inspection team uses statistical process control methods to demonstrate the techniques we use for supervising the PCB assembly process.

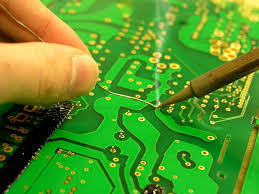

For leadless and BGA component assembly, we use modern techniques such as X-ray Inspection to check the soldering on the joints. We use Automatic Optical Inspection for verifying other solder joints, component orientation and placement. We can provide any additional information regarding our quality methods if the customer requires. We do not charge our customers extra if they require quick shipping of first assembled PCBs or any modification of services.

Also Read: KEY ELEMENTS OF AN IDEAL PWB MATERIAL FROM RUSH PCB INC.

Once the customer receives the first article PCB service boards, they test the boards and inform us of any changes necessary. We take up the required modifications in the programming of our machines and other set-up for the PCB assembly line at no extra cost to the customer.

Fist Article Inspection

First article Inspection is a complete, independent, and documented physical and functional inspection process. The intention is to verify the production methods used by the PCB manufacturer have produced an acceptable PCB as specified by the engineering drawings, specifications, and/or other applicable design documents. The purpose of a first article inspection is to provide objective evidence that all design and specification requirements are exhaustively verified and recorded.

However, sometimes suppliers and OEMs are unaware of the purpose and importance of first article inspection and this ultimately results in loss of money and time, creating havoc in both design and production. In most cases, a customer design center initially expects a qualification report for a new PCB verifying all design characteristics have been met either through inspection, test, analysis, or demonstration. The qualification report should capture individual design characteristics, including reliability data. This may sometimes require destructive testing. On qualification of a PCB, the supplier is ready to go turnkey, and at this stage, a first article inspection is required.

Why First Article Inspection?

Basically, the qualification report qualifies the processes used by the manufacturer, and the first article inspection verifies that these processes output a PCB as expected during normal production builds. First article inspection does not apply to procured vendor parts. Typically, it is used when the manufacturer builds to the customer’s technical data package, and the supplier has never previously built the PCB.

The first article inspection is a standard process to ensure the design characteristics of a PCB forwarded to the manufacturer actually meet design intent when the PCB is actually produced. The customer may repeat the first article inspection entirely or in part if there are changes such as:

- Change in the source or location where the PCB is produced

- If the design change significantly affects the form, fit, or functioning of the PCB

- If there is a significant change in the processes related to manufacturing, assembly, inspection, or testing

- If any manufacturing equipment has undergone a significant change

- If a natural or man-made occurrence adversely affects the manufacturing processes

- The production process has been interrupted for a significant amount of time

- There is significant degradation is test yields

- Any change in manufacturing and/or test personnel on the product line

- Any change in a vendor supplied item with an age factor or revision factor

Therefore, it is necessary for our customers to clarify the purpose of the first article inspection so that Rush PCB is able to mitigate the issues described above. Therefore, Rush PCB never treats first article inspection as just another check in the box, as many other suppliers do.

Also Read: PROBLEMS WITH THE GERBER FILE FORMAT AND SOLUTIONS

Importance of First Article Inspection

First article assembly and inspection offer key product characteristics that drive product performance. If the first PCB from the production process is not correct, then it is likely that other PCBs produced will also not conform. For this reason, Rush PCB ensures that prior to the release of a shipment, our quality engineer reviews the first article inspection in detail to verify items have passed, and no steps skipped or any other mistakes made. Our quality engineer also validates that all the requirements mentioned, such as notes on a drawing, are given a careful review to ensure the PCB meets all design requirements. The recorded results indicate how far the recorded value is from the nominal value. This data indicates the amount of process shift, and whether the deviation is significant from the expected nominal.

Conclusion

It is important the first article inspection report is in an organized format, easily readable by the supplier and the customer. For instance, anyone should be able to locate a certificate of conformance for any part of the PCB or PCB assembly in the report.