Contrary to popular belief that automation is a peril to be avoided at best, Rush PCB Inc advises dependence on the advancement of technology. In fact, without automation there will likely be no growth at all, especially in the manufacturing sector. Since Henry Ford started the first assembly lines, there has been no looking back for automation. Rather, it is become the key to improving the efficiency of the industry.

The story is the same for PCB or printed circuit board manufacturing and assembly automation. Advances in automation gives us the high-density, high-speed, complex multilayered circuit boards that run our computers, operate our vehicles, ships, aircraft, and satellites. They help us communicate all over the world, educate and entertain us through smartphones, and much more. To streamline production according to the needs of today’s technologies, PCB assemblers are adopting newer and better ways to improve their techniques of manufacturing. This article discusses some basics of PCB assembly automation for streamlining production.

Benefits of Automation

Electronics is continuously shrinking in form to meet the requirements of evolving technologies. This is evident for IoT devices, demand for which is growing at phenomenal rates. While PCB manufacturing is growing to supply these needs, the extended industrial systems that assemble and test the boards is also growing along with it.

One of the ways for PCB assemblers to stay ahead of these burgeoning demands has been to update their manufacturing processes. For instance, from manual operations in its infancy, PCB assembly has come a long way. The compact and miniature PCBs are all mass produced with the latest automated assembly processes, bringing innumerable benefits like:

Cost Reduction — Automation reduces the amount of manual assembly time and labor, which in turn, reduces time to assembly and its labor cost.

Faster Assembly — Automated assembly allows achievement of much faster rates as compared to manual assembly.

Lower Errors — Automation eliminates the human errors that manual assembly brings into the process. The random nature of human errors can be difficult to identify and eliminate.

Better Quality — The design of automated assembly machines allows delicate tasks to be repeatedly achieved at consistent levels of quality that is impossible with manual labor.

Miniaturization — Electronic components are now so small that it is no longer possible to assemble them manually. Automated assembly machines are the best way to handle them.

Looking for Automation

The best way to understand PCB assembly automation is to visit a contract manufacturer who builds PCBs. The amount of automation already available is astounding. For instance, automation sorts and disperses components, places components on boards, applies sealants, tests boards, and packages the final products.

For faster assembly, PCB manufacturers and assemblers are maximizing the use of automation. For instance, PCB assemblers use automation for:

- Component identification, marking, and labeling.

- Dispensing solder paste in specific places on the board.

- Picking and placing components on a board.

- Soldering the placed components, typically using reflow ovens or wave soldering systems.

- Routing to separate individual boards from panels.

In addition to the above, there are automated testing processes, like:

- Visual inspection of the board using optical and X-ray systems.

- ICT or In-circuit test systems for verifying individual net connections and the manufacturing integrity of a PCB

- Flying probe test systems for verifying the electrical characteristics of a board.

- Functional test systems to verify the functionality of the assembled board.

Apart from the above automated systems that are directly necessary for PCB assembly, there are many others that facilitate the smooth working of the entire assembly line. These are necessary for the logistics, tracking, and general movement of goods:

- Conveyors for material and boards transportation.

- Barcode readers for processing and tracking boards and components.

- Component delivery systems for feeding components to pick-and-place machines

- Packaging systems for sealing and dispensing final PCB products.

All the above automation is necessary for the smooth and effective working of the entire PCB manufacturing and assembly plant.

How Automation Works

With the advancement of technology, most electronic components have grown both sophisticated and smaller, making it difficult to handle them manually. This has necessitated the use of automated systems to handle them during assembly of PCBs. In addition to making the assembly process more efficient, these automated systems have enabled higher production outputs, higher reliability, better quality control, and easier handling of complex boards. Automation is necessary at various stages of PCB assembly:

Component Identification, Marking, and Labeling

Most SMD electronic components are available from their manufacturers in tubes, reels, trays, and other packaging systems that allow them to be fed directly to the pick-and-place machines. However, assemblers need to identify them, mark them for a specific project, and label them accordingly. Automated storage systems help in cataloging the components in the inventory, so they can be easily extracted for the assembly.

Dispensing Solder Paste

All boards that must undergo a reflow soldering process require a dispensation of solder paste at the correct locations. Automated machines guide and lock the PCB and accurately position a stencil over it. A dispensing arm them either sprays of rolls soldering paste on the stencil. Openings in the stencil allow a correct amount of solder paste to be deposited on the board underneath. The machine them removes the stencil and propels the board to the pick-and-place machine. The solder paste dispensing machine finely controls the volume and direction of solder application to avoid wastage. Before the board moves to the pick-and-place machine, an automated SPI or solder paste inspection stage helps to control failure in the solder paste dispensation stage.

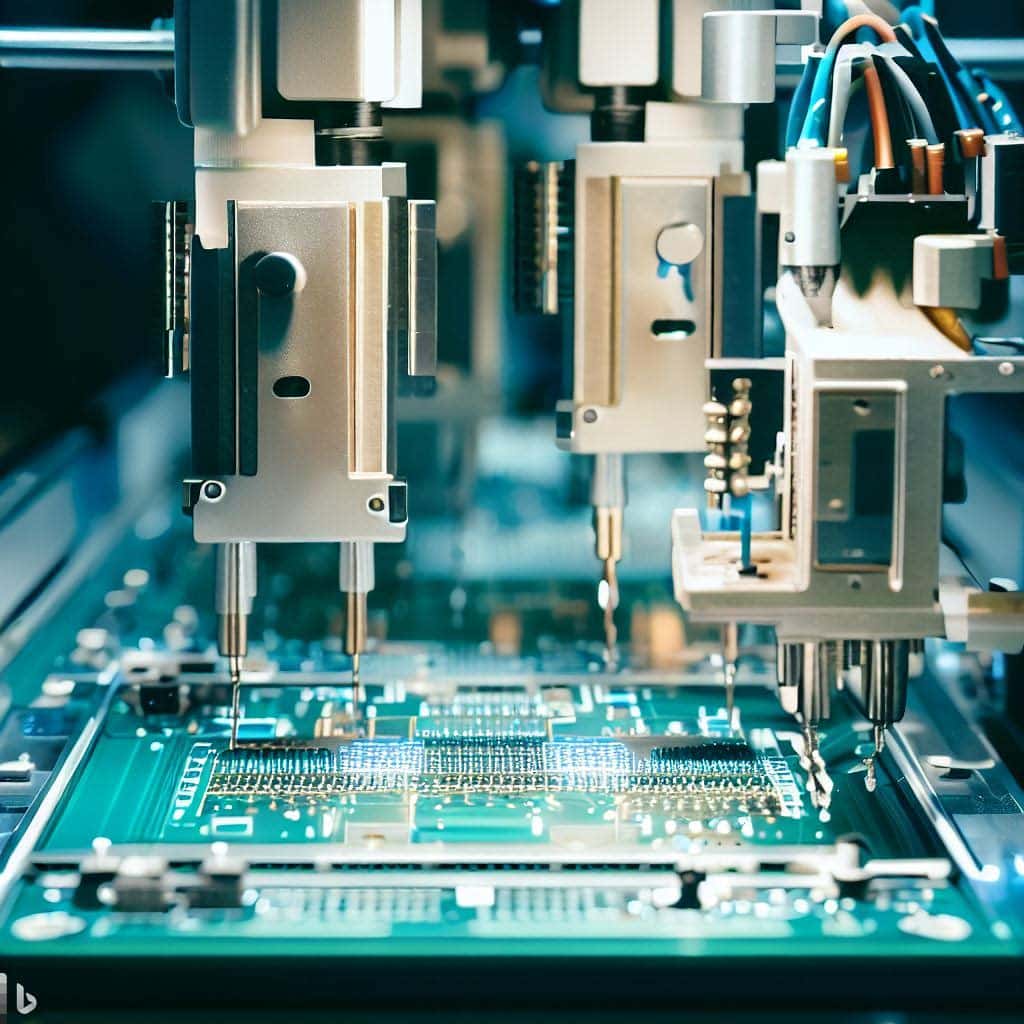

Pick and Place Components

Operators program the pick and place machine for mounting a specific PCB. They also feed the machine with the correct set of components. Once operating, the machine places and locks the board, picks the right component and places it at its designated place on the board. Usually the machine has multiple heads that can pick and place many components at a time. Modern pick-and-place machines offer fine-tuned component handling capabilities, allowing lifting, orienting, and placing components in just the right position.

The process of picking and placing components is one requiring the utmost precision and accuracy in the entire PCB assembly sequence. The complexity of the process is compounded by the components themselves being highly miniaturized, and the mounting density of the board.

Board Traceability

As the board travels through the assembly line, factory automation keeps track of it as it moves from one station to the other. This is usually done by placing a tracking device like a barcode on the board. As the PCB reaches a station on the conveyor, a barcode scanner reads the code to track and monitor production speed. This helps to identify inefficiencies in the production line, and pinpoint any bottlenecks.

Testing

With the complexity involved in assembling a board, testing it after assembly is essential to ensure product quality. Assemblers typically employ AOI or automated optical inspection methods to identify boards with missing, misplaced, or wrongly mounted components, and shorts or dry solders.

Complex boards may have various types of components that do not subject themselves to optical inspection. For instance, there are BGAs with all their connection points below the body of the component. They need special automated inspection methods utilizing X-rays.

Next in line is the in-circuit test systems for verifying the continuity of tracks, and interconnections between components. The test system uses various probes that connect to designated test points under the board, and a programmed computer logs all the readings from each probe. Comparing the readings with those belonging to a known good board verifies the board’s integrity.

Assemblers use another test system involving flying probes for verifying the functionality of the assembly. Two or four probes connect to dedicated test points on the board, while a highly technical software runs to verify that the PCB and its components are functioning appropriately.

Each of the above test procedures requires advanced testing capabilities, and assemblers incorporate them in the test systems as necessary.

Packaging

Thanks to automated systems in PCB assembly lines, not only is production streamlined as above, it is possible to achieve substantial output volumes. Further automation is necessary to handle the finished products for sealing and packing them before dispatch to their customers.

Packaging is the last stage of PCB production. This stage requires careful packing to protect the products from damage during transportation and storage. While a manual packaging process is slow, labor-intensive, and prone to mistakes, automation helps with greater speed and accuracy. Most packing machines have a conveyor belt systems, an arrangement for automatically wrapping and sealing the board assembly, and packing them in boxes, ensuring the contents stay secure during transportation.

Latest Trends in PCB Assembly Automation

Most PCB assembly lines adopting automation for streamlining production also have failure prevention mechanisms to ensure the PCB assemblies are of designated quality. This includes the SPI or solder paste inspection, the AOI or automated optical inspection, and ICT or in-circuit testing.

However, all the above methods to locate failures are reactive, and require spending additional efforts to inspect and rework the faulty PCBs. Additionally, these methods cannot guarantee the process performance of the assembly processes at a high level. The recent trend is to move towards IAPIS or intelligent assembly process improvement systems in smart manufacturing. IAPIS systems integrate the multi-response Taguchi method and the k-means clustering methods to formulate a proactive approach for investigating and managing the process performance.

The idea is to transform the manufacturing processes, making them pro-active and automated to align with objectives in smart manufacturing. The objective is to improve manufacturing performance using data analytics. Smart manufacturing involves six major parameters:

- Data

- Predictive Engineering

- Sustainability

- Resource Sharing and Networking

- Manufacturing Technology and Processes

- Materials

Today, data-driven approaches are improving processes in the manufacturing industry, while there is preservation and extraction of past and new expert knowledge in manufacturing.

Conclusion

As leaders in the PCB manufacturing industry for above two decades, Rush PCB Inc has seen its share of new technologies revolutionizing these industries. We have our own challenge of using these technologies for developing automated solutions that are not only more efficient and reliable, but also more profitable as compared to previous solutions. The PCB industry is always on the lookout for innovative ways to get the job done. We model our assembly methods with advanced monitoring systems to allow us trace components through the production system.