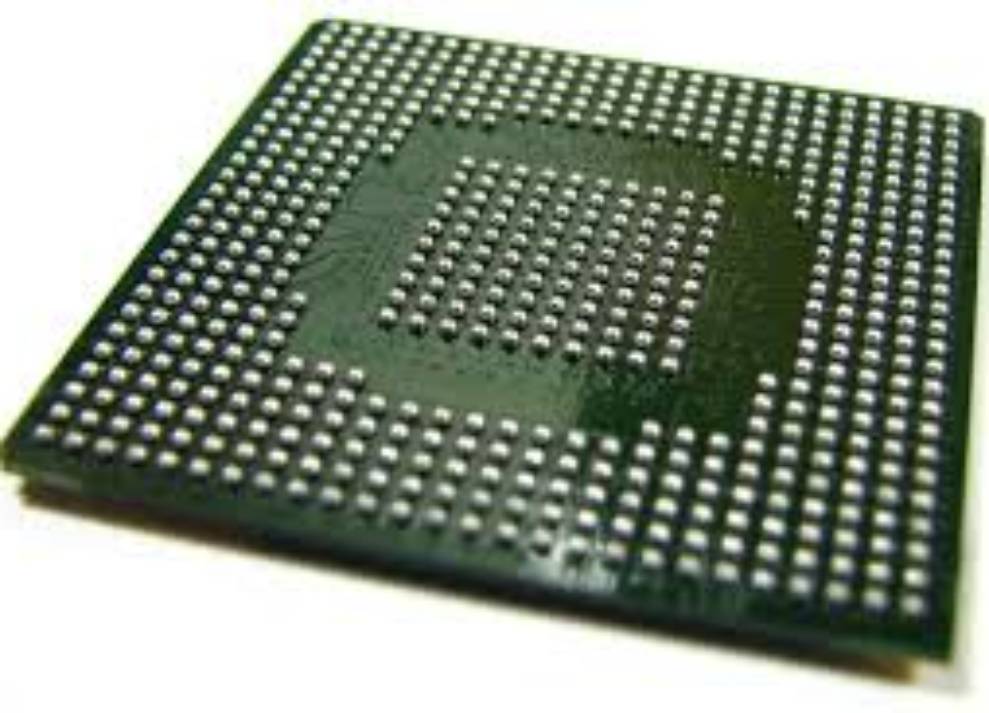

BGAs, or Ball Grid Arrays, require special mounting practices. A BGA is a Surface Mount Device (SMD) with a pattern, or array, of solder pads across its bottom side. This ball configuration provides the flexibility that these components require during thermal cycling (hot/cold) without stressing the physical and electrical connections made by the balls between the component pads and the PCB land pattern.

Attachment of the BGA to the PCB is made by stencil printing solder paste onto the PCB’s land pattern pads, then placing the BGA with its spheres attached onto the pattern, with the spheres contacting their corresponding pads and pressing into the solder paste. The BGA is then reflow soldered in a conveyorized oven.

Ball Grid Arrays PCB Assembly

The BGA provides a greater number of interconnections to the PCB than is available on a conventional quad-flat pack IC; this is the primary advantage of the BGA.

The BGA provides a greater number of interconnections to the PCB than is available on a conventional quad-flat pack IC. It is precisely placed on the printed circuit board so the pads on the BGA match with pads of the PCB. The BGA and the PCB are then heated with just enough heat for the solder to reflow, joining the BGA and the PCB together.

BGA Advantages

The BGA uses surface mount technology: it connects to the top layer of the PCB only, allowing circuit traces to be routed underneath, and it provides for High Density Interconnections (HDI) with its efficient use of board space.

The internal connections (between the silicon die and the BGA pads/balls), are shorter, allowing for greater speed with less inductance. Heat, too, is less of a problem because the BGA is soldered directly to the board.

Among the uses for Ball Grid Arrays are audio, video, data storage and processing, communication equipment, medical equipment, radar/sonar, 3D graphics, and imaging.

Contact us at [email protected] for more information on Ball Grid Array technology.