Rush PCB Inc recommends a robust inspection process before concluding the assembly process of a printed board assembly. That is because the inspection process has the ability to uncover hidden defects—allowing the assembler to save precious time, while also protecting against expensive repairs at a later date.

Types of PCB Inspection Processes

Depending on the requirement and customer demands, the assembler can undertake several types of inspection processes for PCB assemblies. Some of them are:

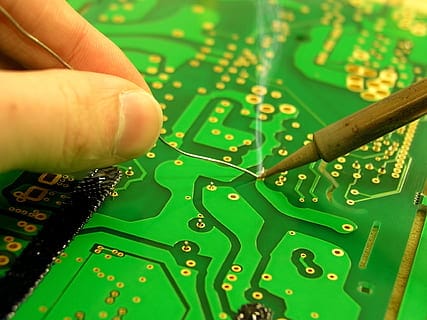

Manual PCB Inspection: This involves manually checking assemblies and inspecting them for defects.

Automated Optical Inspection (AOI): Using an optical system to capture images of the assembly and comparing them on a computer for identifying defects.

Automated X-Ray Inspection (AXI): An optical system may not be adequate for complex and dense assemblies. Optical systems using visible light rays cannot look under BGA chips to view hidden solder joints. X-rays are necessary to view these hidden joints.

X-Ray Inspection: Inspecting complex boards with many layers is impossible without using X-rays. Inspecting with X-rays helps to uncover defects in buried vias, and defects in internal layers.

Defects Uncovered by Inspection Processes

Some common defects easily uncovered by PCB inspection methods are:

Footprint Errors: Complex boards can have several types of ICs with different footprints. The designer downloads the necessary footprints from the CAD library while designing the board. If the library does not have the proper footprint, chances of downloading a wrong footprint pattern increases. A manual inspection or an AOI method can spot this type of defect easily as they are usually present on the top or bottom surface.

Defective Blind/Buried Vias: Complex boards using multiple layers use blind and buried vias to interconnect layers. Visual inspection or AOI processes cannot ascertain the Integrity of these vias as they are hidden in the inner layers. Using AXI or X-Ray inspection methods helps to penetrate the substrates to assess the health of the hidden vias.

Soldering Defects under BGAs: BGA ICs have solder balls on their underside and require proper soldering to the pads for functioning. Manual inspection or AOI cannot detect soldering defects under the IC, as the plastic body of the BGA IC hides the soldering underneath. These defects can only be assessed with AXI or X-Rays inspection methods.

Solder Voids: Quality soldering is very important for the reliability of the PCB assembly. Presence of moisture can lead to formation of voids in the solder joint. If the void is on the surface of the solder joint, it may be detected by manual inspection or AOI. However, AXI and X-ray inspection is necessary to detect presence of voids under a solder joint.

Pinhole Defects: Pinholes in the barrel of plated through holes (PTH) usually form during the electroplating process and may lead to a breakdown of the PTH producing electrical discontinuity. The only possible way of detecting these defects is by using X-Rays.

Missing Components: Errors in programming the pick and place machine or in setting up the reels of SMDs can lead to the machine not mounting some components. It is easy to spot missing components by a visual examination of the board as well as by AOI.

Advantages of PCB Inspection

As is evident, PCB inspection is an important process stage, offering several benefits and ensuring a firm control over the quality of the assembly. An inspection stage at an opportune position in the assembly chain can actually help improve the throughput of the PCB production. For instance, if a particular defect happens to occur repeatedly, the operator can change the process parameters to stop it from recurring.

A PCB inspection stage may look like an impediment to the smooth flow in the production line. It may also look like adding to the cost. However, a comparison of the time and cost involvement of a PCB inspection stage to that of rectifying a failure of the product at a later stage, will convincingly demonstrate the importance of PCB inspection.

Inspecting PCBs after each process step can help to ensure setting the correct process parameters for achieving consistent quality across the production line. In the absence of a proper inspection protocol, defective boards may reach the OEM, and then on, to the market as flawed products. This can lead to expensive recalls, leading to an extensive loss in reputation both to the OEM and to the assembler. If the product is a medical device or an automotive component, the damage could be more serious.

Depending on the type of defect, installing PCB inspection and functional testing stages will not only ensure adequate board performance, but also help maintain acceptable cycle times. Employing the best inspection techniques for the needs of the assembly project can help significantly in ensuring PCB integrity.

Conclusion

Rush PCB Inc is fully equipped to handle all types of PCB manufacturing and assembly. With our state-of-the-art machinery and talented team of experts, we can meet any industry standard for quality and testing. Our vast portfolio of satisfied customers are the biggest testimony to our success. For any requirement of PCB manufacturing, assembly, inspection, and testing, feel free to contact Rush PCB Inc.