According to Rush PCB Inc, printed electronics is a broad term encompassing all printing methods manufacturers use to create electronic devices, including flexible printed circuit boards. This printing can be on a variety of substrates. Earlier, printed electronics meant plastic or organic electronics that made use of one or more types of inks based on carbon compounds.

With the explosion of demand for thinner and wearable electronics, printed electronics are becoming the basis of fabricating antennas, flexible keyboards, electronic skin patches, and many more. With the evolution of printed electronics, it is now possible to create electronic circuits quite quickly and inexpensively. Right now, printed electronics is the fastest-growing technology and is on its way to becoming a valuable technique for several industries like transport, media, aerospace, and healthcare.

What is Printed Electronics

Printed electronics is a new way of manufacturing electronics with an old manufacturing method using newer types of materials. Although different kinds of applications are widely using printed electronics in various ways, the technology is still under development.

For instance, using silicon for printed electronics is of major interest, and this is resulting in low-cost flexible displays. Printed electronics use various types of inks with nanoparticles of metals or ceramics that help in creating rapid flow in electronic devices. It is easy to manipulate nanoparticles and assemble them reversibly in many ways, making them useful in optical, electrical, or electronic equipment.

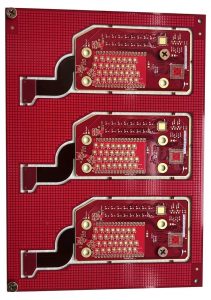

Printed electronics processes use printing technology for producing various types of electronic goods. These include RFID, sensors, displays, and electronic flexible circuits. Printed electronics make use of organic semiconducting and conducting materials along with inorganic materials.

The printed electronics arena is very wide and includes a huge array of different materials and printing technologies. As it is already providing a new direction and functionality to packaging, printed electronic technology is becoming a front contender for the food packaging industry.

Applications of Printed Electronics

With the advancement of printed electronics technology, more and more products are using it. These include intelligent labels, flexible screens, intelligent packaging, interactive posters, books, and upholstery. With manufacturers using thinner substrates, printing materials are becoming increasingly thinner, lighter, and flexible enough to enable them to integrate into existing products.

The market for printed electronics is expanding fast. By 2025, the market is expecting printed electronics and flexible electronics to grow to over US$73 billion. However, not all types of printed electronics will have an equal share of that market—some markets will reach maturity sooner than others will. At present, the market is already expanding for technologies using printed electronics that include OLEDs, PhotoVoltaic applications using conductive inks, and printed glucose sensors.

The Internet of Things, or IoT, is also a reason for the growth of printed electronics. This is because IoT needs a lightweight and low-cost electronics for sensing, storing information securely, and transmitting data. For this, the IoT market is using printed memory, sensors, and communication devices. As the IoT market may reach US$7.1 trillion very soon, researchers are working on new types of printed electronics involving more sophisticated and intricate printing processes, along with stamping techniques capable of printing tiny transistors that can control individual pixels in touch screens and high-resolution displays.

So far, they have succeeded in fabricating a stamp for transferring printing inks onto flexible or rigid surfaces. This new printing technique is an inexpensive but fast way to fabricate electronic surfaces for newer applications.

Advantages of Printed Electronics

With printed electronics becoming flexible, secure, and cost-effective, it has become an attractive technology for a wide range of industries. Mass-produced electronics is usually associated with high costs and technical constraints. Printed electronics have the potential to reduce this substantially, as it requires fewer input materials and less energy for fabrication.

Printed electronics is also opening up newer possibilities for creating flexible devices that are still not available in the market. For instance, companies are using printed electronics for identifying credit cards, banknotes, legal documents, and others with unique printed signatures.

The photovoltaic industry is also benefiting from printed electronics, which is useful in creating cheaper polymer electronics. This is significantly changing the scenario in solar power projects.

Summing up, the benefits of printed electronics are:

- Inexpensive technology

- Flexible form factor

- Easy to produce

- Easy to integrate

- Facilitates the development of non-conventional but functional electronic devices like smart labels, flexible displays, active clothing, animated posters, and more

Printed Electronic Challenges

Although it is a fast-growing technology, printed electronics have their own challenges. One of the major challenges is developing the best conductive inks for printed electronics. The other is to find materials that will improve the characteristics of printed electronic products. Most processes that printed electronics use are not yet established, requiring trial-and-error and testing to make them succeed.

Conclusion

OEMs are using printed electronics to make everyday objects smarter. This includes printed batteries, flexible circuit boards, antennas, sensors being integrated into the plastic film, fabric, paper, metals, and 3-D printed objects. Printed electronics are opening up innovative possibilities for electronic devices and applications. Rush PCB is a leading manufacturer of flexible printed circuit boards in the USA.