Dielectric materials are a key part of high-performance PCBs (Printed Circuit Boards), which are used in advanced electronics like aerospace systems, 5G networks, and high-speed data devices. Selecting the proper material is essential, as this will affect the electrical performance of the board. Rush PCB Inc. can help determine the type of material best suited for a specific design. We can help you choose specific materials from a large list of suitable PCB materials, depending on the sophistication of the electronic signals running on the PCB. Our engineering team at Rush works with the customers closely right from the concept stage of the design to review the aspects related to the specialized nature and domain of the application, to selecting the right type of materials to support and guarantee a reliable and functional product meeting the targeted parameters of performance.

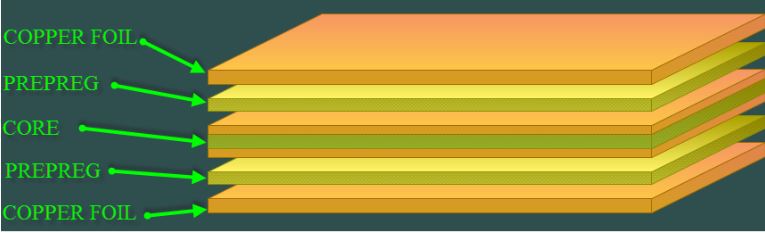

Materials such as FR-4, polyimide, and PTFE-based laminates help control signal loss, manage heat, and provide electrical insulation between copper layers. These materials are specially designed to support high-frequency signals, resist high temperatures, and maintain reliability in demanding environments. But what are these materials really made of? How are they manufactured? What makes them suitable for high-speed, high-frequency designs, and how can we process them to get the best performance? By exploring their structure, properties like dielectric constant and thermal conductivity, and how they’re used in PCB fabrication, you’ll gain a deeper understanding of what makes a high-performance board truly reliable.

Naming Convention:

The common names used for materials in printed wiring board laminates, such as “Epoxy”, “Polyimide”, and “PTFE”, have traditionally referred to the primary resin systems used. However, as high-performance applications evolve, new materials and combinations are being introduced, making the old generalizations less accurate. For example, terms like “Epoxy” or “FR-4” are too broad to cover the specific needs of modern products like Low Flow, Multifunctional, Lead-Free, CAF Resistant, High-Speed Digital, and “Green” epoxy materials. This shift is reflected in the growing number of specifications in IPC-4101, the industry standard for laminates and prepregs. Materials are now categorized based on their properties, resin system, application, or substrate type.

Most resins used in the electronic laminates industry are thermosets, meaning they cure into a hard final product, as opposed to thermoplastics, which can be melted and remelted. A key exception is PTFE (polytetrafluoroethylene), commonly known by the DuPont trade name Teflon® (though other manufacturers also produce PTFE). PTFE is used in laminates for microwave and RF applications due to its excellent dielectric properties, making it ideal for high-frequency use.

Resin Systems:

Here is a list of common resin systems used in printed circuit boards (PCBs), along with their key features and typical applications.

Epoxy Resins

Epoxies are the most common resin used for printed wiring boards (PWBs). They are cost-effective, versatile, and can be formulated with Tg values ranging from 110°C to 170°C. Epoxies work well with most PCB fabrication processes, making them ideal for consumer electronics and general applications. Epoxy products are generally classified into three basic categories based on their Tg (glass transition temperature):

- Low-end traditional systems (Tg range 110-130°C)

- Modified systems blended with multifunctional resins; (Tg’s range 135-160°C.)

- Pure Multifunctional epoxy systems; (Tg’s 170°C or above)

Multifunctional epoxies have higher Tg and better resistance to chemicals; hence, they are ideal for harsh processing environments and provide excellent PTH reliability and resist melting, making them suitable for high-layer-count and high-performance boards.

Low-Flow Epoxies

Low-flow epoxy systems are formulated to limit flow, making them ideal for applications like heat sink bonding and rigid-flex PWB (Printed Wiring Board) manufacturing. These systems are available in a variety of glass transition temperatures (Tg) and flow characteristics to suit different needs.

Blend of Resin Systems

Various resin system blends are available. A common misconception is that the resulting properties of a blend will simply fall midway between those of its individual components. However, this assumption lacks a scientific basis and can lead to problematic outcomes.

Polyimides

Polyimide resins are chosen for applications or processes involving high temperatures due to their exceptionally high glass transition temperature (Tg), typically above 250°C. This makes them ideal for a range of demanding environments and applications.

- Polyimides reduce strain in PTHs during high-temperature processes like solder reflow, helping prevent latent defects

- They resist pad lifting during repeated repairs or re-soldering.

Types of Dielectric Materials and Their Common Usage

| Type | Description | Common Usage |

| FR-4 (Epoxy Resin + Glass) | The most common, general-purpose dielectric. Moderate performance, low cost. | Consumer electronics, computers, and industrial PCBs. |

| Polyimide | High-temperature, flexible material. Very durable. | Flex circuits, aerospace, and automotive. |

| PTFE (Teflon) | Very low-loss, excellent high-frequency performance. Soft and chemically resistant. | RF/microwave circuits, antennas, satellite, radar. |

| Ceramic-Filled PTFE | PTFE mixed with ceramics for better mechanical strength and lower expansion. | High-end RF/microwave PCBs, 5G boards. |

| Cyanate

Ester Resin |

Extremely low loss and high thermal stability. | Super high-speed digital, aerospace, high-frequency communication. |

| Hydrocarbon-Ceramic | Cheaper alternative to pure PTFE; good for RF. | Mid-range RF boards, base stations, and wireless systems. |

| Liquid

Crystal Polymer (LCP) |

Very low dielectric loss, moisture resistant, flexible. | Millimeter-wave (60GHz+), wearable tech, smartphones. |

Key Elements of Dielectric Materials:

With the wide range of materials and applications available, the idea of an “ideal laminate” has become unclear. A material that works well for high-temperature applications may not be suitable for microwave or high-speed digital designs. Therefore, while certain properties are universally important, each design team must prioritize them based on its specific needs. No single material can perfectly fulfill all desired properties. This article provides a set of common properties that designers can use to make informed choices during the design process.

Glass Transition Temperature (Tg)

Tg serves as a rough indicator of Z-direction expansion and is often used as a proxy for plated-through-hole reliability. Epoxy systems with Tg values around 170°C are commonly used in applications with less demanding processes or in-use temperatures. While Tg is a useful reference for traditional epoxy and polyimide materials, it is less reliable for assessing the performance of highly filled systems or non-traditional resin systems used in high-frequency, low-loss applications, where properties are influenced by a combination of components.

Thermal Decomposition Temperature (Td)

It represents the temperature at which a material starts to degrade. Td can range from about 300°C for many epoxy systems to over 400°C for some polyimides. While some datasheets list Td as the temperature where the material loses 5% of its weight, a more reliable indicator is the onset temperature, when significant weight loss first occurs. By the time a material has lost 5% of its weight, it may no longer be suitable for many applications.

Dielectric Constant and Loss Tangent (Dk & Df)

The dielectric constant (Dk) determines the speed at which an electrical signal travels through a dielectric material, with signal speed measured relative to the speed of light in a vacuum. A hard vacuum has a dielectric constant of 1.00. Higher dielectric constants slow down signal propagation. Loss Tangent or dissipation factor (Df) measures how much signal power is lost as it travels along a transmission line on a dielectric material. Let’s try to understand Dk and Df with the following example.

Imagine sending a signal through a material like driving on a road. The dielectric constant (Dk) is like the speed limit; the lower it is, the faster your signal can go. It means that a low Dk allows signals to move more quickly, which is especially important in high-speed circuits where timing and signal clarity matter. The loss tangent or dissipation factor (Df) is like road bumps; it shows how much of the signal gets weakened or “lost” as it moves along.

Different materials have different Dk and loss values depending on what they’re made of and how they’re tested, so there isn’t one perfect material for every job. For most high-speed electronics, materials with a Dk between 3.0 and 3.5 (like some modified epoxies) work well and aren’t too expensive. But for things like antennas or radio systems, where keeping a strong signal matters more, materials like PTFE (which has a very low Dk and barely any signal loss) are a better choice.

Coefficient of Thermal Expansion (CTE)

CTE measures how much a material expands with heat (in parts per million per degree Celsius). It’s important to match the CTE of the laminate with the components attached to it, like surface-mounted devices or internal layers, to avoid stress or damage during temperature changes.

Z-Direction Expansion

This is how much a printed circuit board (PCB) material expands through its thickness (top to bottom) when it heats up, especially important during soldering or other high-temperature processes. Now, inside a PCB, plated through holes are lined with copper. Copper expands at a rate of about 17 ppm/°C. If the board material expands much more than the copper, it can stretch or crack the copper inside those holes, causing failures.

Thermal Conductivity (Tc)

As circuit boards get smaller and hold more parts, they produce more heat in less space. This extra heat can be a big problem; even just a 10°C rise can double the risk of parts failing.

To control the heat, the board materials need to move heat away from hot areas. New materials with thermal conductivity between 1.0 and 3.0 W/m-K work much better than older ones like epoxy, which only rate around 0.25 to 0.3 W/m-K. The challenge is to find materials that cool well but still let the board work properly for electronics.

Lead-Free Compatibility

Lead-free soldering uses higher temperatures—about 30°C to 50°C hotter than traditional lead-tin solder. So, the materials used in circuit boards need to handle this extra heat without breaking down.

To be called lead-free compatible, a material usually needs:

- A Tg (glass transition temperature) above 155°C

- Strong heat resistance (passing T288 and T300 tests)

- A Td (decomposition temperature) over 330°C

- A CTE (expansion rate) below 3.5%

CAF Resistance

CAF (Copper Anodic Filament) growth happens when copper slowly moves and builds up between holes in a circuit board, causing short circuits or unreliable performance. This can occur when there’s:

- A voltage difference between holes

- Ionic contamination (leftover residues)

- A small gap between the resin and glass fiber, which creates a path for copper to migrate

CAF is a big concern in high-performance, long-life boards, like those used in servers, because they run continuously and need to be very reliable.

There’s no simple test to say if a material is CAF-safe, because board design, materials, and manufacturing quality all play a role. However, laminators reduce CAF risk by using:

- Special resin formulas

- Treated glass fiber surfaces

- Careful processing techniques

All of this helps the board resist copper migration and stay electrically stable over time.

Pros and Cons of Dielectric Materials

| Material | Pros | Cons |

| FR-4 (Epoxy Resin + Glass) | – Low cost

– Good mechanical strength – Easy to fabricate |

– High dielectric loss at high frequencies

– Limited thermal stability |

| Polyimide | – Excellent thermal stability

– High mechanical flexibility – Good chemical resistance |

– More expensive than FR-4

– Higher moisture absorption |

| PTFE (Teflon) | – Extremely low loss tangent (great for RF/microwave)

– Very low dielectric constant |

– Soft and hard to handle

– Expensive – Needs special processing (plasma treatment) |

| Ceramic-Filled PTFE | – Low loss

– Better mechanical stability than pure PTFE – Good dimensional stability |

– Still costly

– Harder to drill and fabricate compared to FR-4. |

| Cyanate

Ester Resin |

– Very low loss

– Excellent for high-speed digital circuits – High temperature stability |

– High material cost

– More sensitive to fabrication defects |

| Hydrocarbon-Ceramic | – Lower cost than PTFE

– Good RF performance – Easier to fabricate than pure PTFE |

– Not as low-loss as pure PTFE

– Slightly higher moisture absorption |

| Liquid

Crystal Polymer (LCP) |

– Ultra-low loss

– Excellent moisture resistance – Flexible and high-frequency capable (up to 110 GHz) |

– Expensive

– Processing needs special setup – Limited PCB fab availability |

Popular Dielectric Material Vendors

- Doosan

- EMC

- Isola Group

- ITEQ

- Nnya

- Panasonic Electronic Materials

- AGC Nelco

- ShengYi Technology

- TUC

- NouYa

- DuPont

- Rogers Corporation

Our Material Selection Guide for Advanced Network and Switch Products

Based on the material properties and construction technologies used in advanced network and switch products, we, at Rush PCB Inc., have classified PCBs into different categories. Each class is paired with PCB materials that are best suited for its specific application.

| Generic Name | Class 1 | Class 2 | Class 2.5 |

| Typical resin type | FR4 Epoxy | Enhanced epoxy blend | |

| Typical glass type | Std. E-glass (Dk ~6.6) | Standerd DK (~6.6) E-glass | |

| Typical foil type | HTE > 4.5 um & RTF | 4.5 > RTF > 2.3um | |

| PCIE classification | High Loss | Standard Loss | Middle Loss |

| PCIe / Ethernet | PCIe | PCIe 3.0 – 4.0 / 40G Ethernet | |

| Ethernet / Infi-Band | < 10Gbps | 10 ~ 20 Gbps | |

| Doosan | DS-7408 | DS-7402 H | |

| EMC | EM 825 EM 827 EM 370 (5) / (Z) |

EM 285 EM 370 (D) |

EM 828 G EM 355 (D) EM 390 |

| Isola | IS 400HR 185HR / 370HR IS 550H |

IS 415 / HR | |

| ITEQ | IT-158 / IT-180A IT-258GA3 IT-189 / IT-180L |

IT-180i IT-150 G / IT-150GTA1 IT-170 GRA / IT-170 GL IT-858 G |

IT-170 GRA-1 IT-150 GS IT-170 GT |

| Nanya | NP-155F NP-175FM NP-175FBH |

NPG-150N NPG-151 NPG-170N |

NPG-171/181 NPG-150 LKHD NPG-150D |

| Panasonic | R-1755C R-1755V R-1755M |

R-1566W (N) | Megtron 2 Megtron 2E |

| AGC Nelco | N4000-20 | ||

| ShengYi | S1000-2 / -2M / H ST110 |

S 7045G Autolad-3G |

S 7038 S 7040 G |

| TUC | TU-668 / TU-768 TU-662 / TU-752 |

TU-862HF TU-747HF TU-865 |

TU-862 (S) TU-747 LK |

| NouYA | NY2170 NY-2150M |

3170HF NY-6180 |

NY3170M |

Class 3 and 4 Products

| Generic Name | Class 3 | Class 4 |

| Typical resin type | Enhanced epoxy / BT blend | |

| Typical glass type | Standard DK (~6.6) & Low Dk (~4.8) glass | |

| Typical foil type | 4.5 > RTF > 2.3um | 2.3 > (RTF-2 / RTF-3) > 1.8 um & HVLP |

| PCIE classification | Low Loss | Very low Loss |

| PCIe / Ethernet | PCIe 4.0 – 5.0 / 100G Ethernet | |

| Ethernet / Infi-Band | 25 ~ 32 Gbps (~ 1.2 dB/in @ 28 GHz) | |

| Doosan | DS-7409 DX DS-7409 DXc DS-7409 DXG |

DS-8502HQ |

| EMC

|

EM 888 (S) EM 526 EM A50 |

EM 888K EM 528 |

| Isola

|

FR 408* FR 408HR* I-Speed |

|

| ITEQ | IT-150 DA IT-170 GRA-2 IT-958G |

IT-968 IT-968 G |

| Nanya | NPG-170D | NPG-188H |

| Panasonic | Megtron 4 / 4S Megtron M |

|

| AGC Nelco | N4000-13* N8400-20 |

N4000-13 SI* N8400-20 SI |

| ShengYi | S 7439 / C S 7040 G SI 10U (S) |

|

| TUC | TU-872 LK TU-872 SLK TU-863+ (T1+) |

TU-872 SLK SP TU-883 C (T2C) |

| NouYA | NY6200 NY3170LK NY3170M2 |

|

Class 5 and 6 Products

| Generic Name | Class 5 | Class 6 |

| Typical resin type | Enhanced epoxy / BT / PPE /PPO blend | |

| Typical glass type | Low DK (~4.8) NE, L, or TD Low glass Dk | |

| Typical foil type | HVLP 1.8um HVLP2 1.2um | |

| PCIE classification | Ultra low loss (I) | |

| PCIe / Ethernet | PCIe 5.0+ / 200-400G Ethernet | |

| Ethernet / Infi-Band | 28 ~ 56 Gbps (1.2 ~ 0.75 dB/in @ 28 GHz) | |

| Doosan | DS-8502HQ (N) DS-7409 DJG DS-7409 DV/DVc |

|

| EMC | EM 891 | EM 890 EM 528K |

| Isola | Tera Green I-Tera MT 40 |

Tera Green 100G Tachyon 100G |

| ITEQ | IT-988 G | IT-968 SE IT-968G SE |

| Nanya | NPG-186 | NPG-186K NPG-198 |

| Panasonic | Megtron 6/T Megtron 6G HF Megtron 6 |

Megtron 6N HF Megtron 6N Megtron 7/7GE |

| AGC Nelco | Meterowave 1000 | MWv 2000 MWv 3000 |

| ShengYi | Synamic 6 Synamic 6Gx |

Synamic 6N Synamic 6Gx(N) Synamic 8G |

| TUC | TU-883 (T2) TU-883A (T2A) TU-885 |

TU-883 SP TU-883A SP TU-933E (T3E) TU-885-SP |

| NouYA | NY6300 NY6300S NY6300SL |

NY-P2E NY-P1 |

Class 7 and 8 Products

| Generic Name | Class 7 | Class 8 / Class 8+ |

| Typical resin type | Enhanced epoxy / BT / PPE /PPO blend | |

| Typical glass type | Low DK (~4.8) NE, L, or TD Low glass Dk | (DK ~4.2) NER / LD II |

| Typical foil type | HVLP2 0.8um HVLP3 0.8um | |

| PCIE classification | Ultra low loss (II) | |

| PCIe / Ethernet | PCIe 5.0+ / 200-400G Ethernet | 800G Ethernet |

| Ethernet / Infi-Band | 28 ~ 56 Gbps (1.2 ~ 0.75 dB/in @ 28 GHz) | 112 Gbps (<0.75 dB/in) |

| Doosan | DS-7409 DV(N) DS-7409 DV(NT) DS-7409 DJG(N) |

DS-7409 DJ(L/N)+ DS-7409 DJ(N2/L2)+ DS-7409 DQN/N2 |

| EMC | EM 891K EM 890K EM 890K (A) |

EM 890 K2 EM 892 K/K2 |

| Isola | Astra MT 77 | Tera Green 400G |

| ITEQ | IT-988G SE | IT-998G |

| Nanya | NPG-198K | |

| Panasonic | HF Megtron 6N Megtron 7N/7GN R5515 77 GHz |

Megtron 8N Megtron 8U |

| AGC Nelco | Meterowave 4000 | MWv 8000 ELL 102 |

| ShengYi | Synamic 8GN | Synamic 9GN Synamic 8GN2 |

| TUC | TU-933+ (T3+) | TU-943SN (T4SN) TU-943SR (T4SR) |

| NouYA | NY-P2 NY-P3 |

NY-P4 |

Contact us at Rush PCB Inc. today for an instant quote.