Rush PCB Inc offers flying probe testing facilities for PCB assemblies. This process is useful for high-speed testing while offering a greater fault coverage. We use an automated system with only a few probes that move along the top and bottom of a board assembly simultaneously. Testing a specific board assembly requires a unique program to move the flying probes from one test point to another.

Why Flying Probe Testing is Necessary?

PCB assemblers prefer using flying probe testing as it offers increased test speeds, and a greater coverage of various types of faults. Not only does it reduce testing times, but also saves on the cost. Unlike ICT or In-Circuit Testing that necessitates using expensive test fixtures, flying probe testing is an uncomplicated setup where a simple alteration in the test program can accommodate design changes in the PCB assembly under test.

With flying probe testing, it is also possible to power up the board, inject signals at specific points, and check for signature outputs at some other specified points. Although flying probe testing requires the designer to add test points at strategic positions on the board, they can also use on-board vias as embedded test points to reduce the number of test points.

What Boards need Flying Probe Testing?

We use flying probe testing expressly for low-volume boards, such as prototype circuit boards. The reason for this is the ease with which it is possible to fit the flying probe system to test a PCB by modifying the system program. In-circuit testing, on the other hand, requires fabricating a bed-of-nails, which is not only expensive, but exclusive for a specific PCB. Therefore, the speed of deployment and ease of using flying probe testing for different PCBs makes it a viable alternative.

Our Capabilities for Flying Probe Testing

At Rush PCB Inc, we use small test probes that require the test contact pads to be as small as 80 microns. Before we take up the flying probe tests, we conduct a few preliminary tests that include:

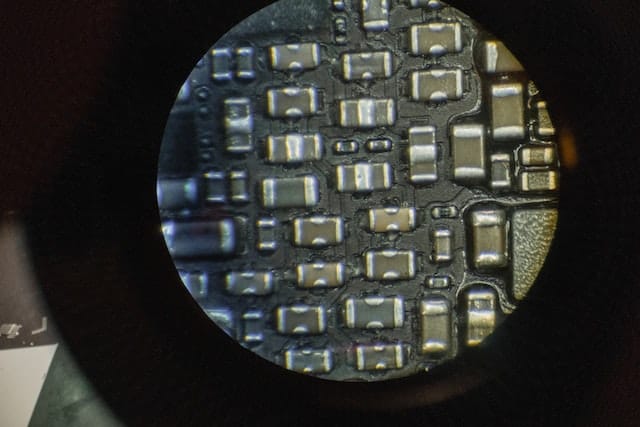

- Manual optical testing using illuminated magnifying glass.

- Automated optical testing for detecting missing and wrong placement of components.

Our flying probe testing includes:

- Testing LEDs functionally, including color and intensity.

- Open or bad soldering of IC pins.

- Circuit power up testing, if necessary.

Advantages of Flying Probe Testing

Flying probe testing of a PCB assembly offers many advantages. These include:

- No fixture requirements as compared to ICT systems.

- Low up-front investment compared to using ICT.

- Minimum programming time.

- Suitable for low volume runs and prototype assemblies.

- Low debugging time.

- Easy way to detect opens, shorts, wrong polarities, missing components, wrong components, and more.

- Non-complicated setup, no need for data communication, or DFM.

- High accuracy results.

- Suitable for single-, double-, and multi-layered boards.

What can Flying Probe Testing Detect?

Only ingenuity limits detecting with flying probe testing. For instance, using flying probes, it is possible to test:

- Opens

- Shorts

- Wrong polarity

- Wrong component

- Missing component

- Resistance value

- Capacitance value

- Inductance value

- Output signature depending on input signal

- and much, much more.

We recommend flying probe testing for PCBs with low-volume builds. Moreover, we also recommend flying probe testing to customers who do not want a functional test for their PCBs after it has passed the visual test.

Some FAQs About Flying Probe Testing

- Why is Flying Probe Testing so helpful?

- First and foremost, it is a high-speed testing method. Second, it is extremely cost-effective and simple. Thirdly, it is well-suited for testing prototypes and low volume runs. Fourthly, one needs to use test points on the PCB, but on-board vias are equally helpful. This not only reduces the need for adding test points on the board, but helps where miniaturization has reduced the form factor of the board.

- How long does Flying Probe Testing take?

- Most run times of flying probe testing vary between 5 and 15 minutes. However, this depends on the size and complexity of the board. For instance, a very large board may take upward of 30 minutes for a complete test run.

- Is Flying Probe Testing complementary to Automated Optical Inspection?

- Yes it is. You can use AOI to verify all components present on the board are in their proper positions. Then flying probe testing complements this by accurately measuring their functioning.

- Where do you mostly use Flying Probe Testing?

- We mostly use flying probe testing for low-volume boards, such as for testing prototypes.

- Are there any advantages of Flying Probe Testing Over In-Circuit Testing?

- In-circuit testing requires a fixture or bed of nails, which has a limitation of pitch, and is therefore, not very helpful for testing miniature boards. On the other hand, flying probes do not require any fixtures, can operate at highly close pitches, and can connect with great precision. For instance, where the minimum pitch for a standard ICT fixture is about 0.5 mm, that for flying probes it can be as low as 0.1 mm. That makes flying probe testing very suitable for testing small form factor boards and highly dense boards also.

Why Rush PCB Inc for Flying Probe Testing?

Rush PCB Inc has over two decades of printed circuit board fabrication and assembly experience. We offer our customers across many industry verticals our high-quality, fully tested boards.

With our testing methodologies, we make sure that our customers do not face the consequences of errors in their boards. We ensure a robust flying probe testing methodology for fast turnaround of the printed circuit boards we fabricate and assemble, especially for prototypes and those with low-volumes. For ensuring the success of our flying probe testing methods, we employ:

- Extensive coverage of tests

- Statistical analysis

- Root cause analysis

- Experienced and expert engineers

For instance, our dedicated expert team works with your engineers to determine the best and the most efficient testing method for your specific project. This depends on your design, quantity of boards in your order, and your specific requirements.

As your contract partner, Rush PCB Inc offers you the edge of our technical expertise, backed by industry best practices that we follow. We make sure we will deliver your board fully complying with your design requirements. Absence of issues in the boards means it is possible to proceed with their assembly without any loss of time. This quick turnaround time allows you to reach your market much before your competitors can.

Therefore, get in touch with us and share your requirements. Upload your design files and BOM to get an instant quote. We can assure you our quote will be comprehensive and competitive.